You are here:Home > News

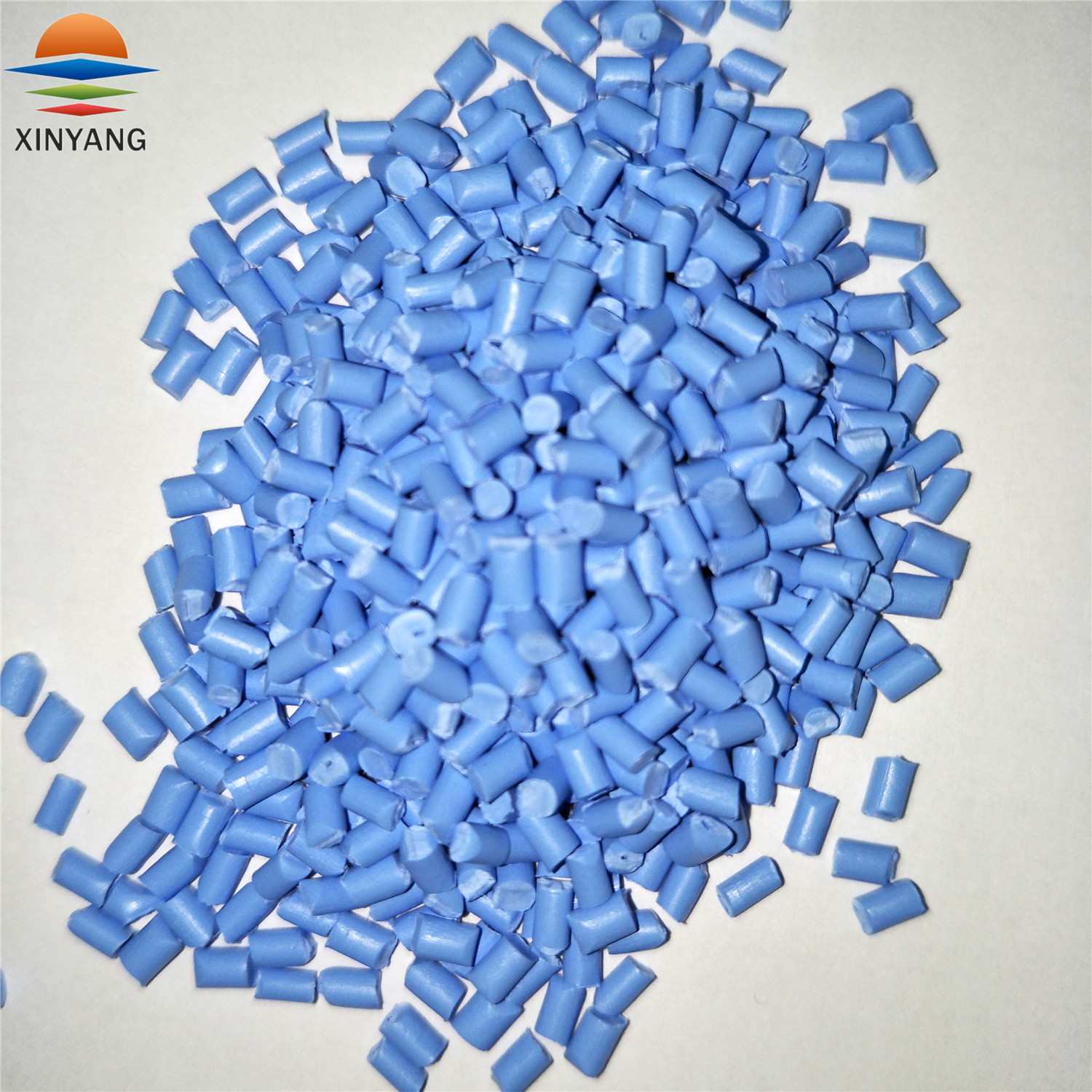

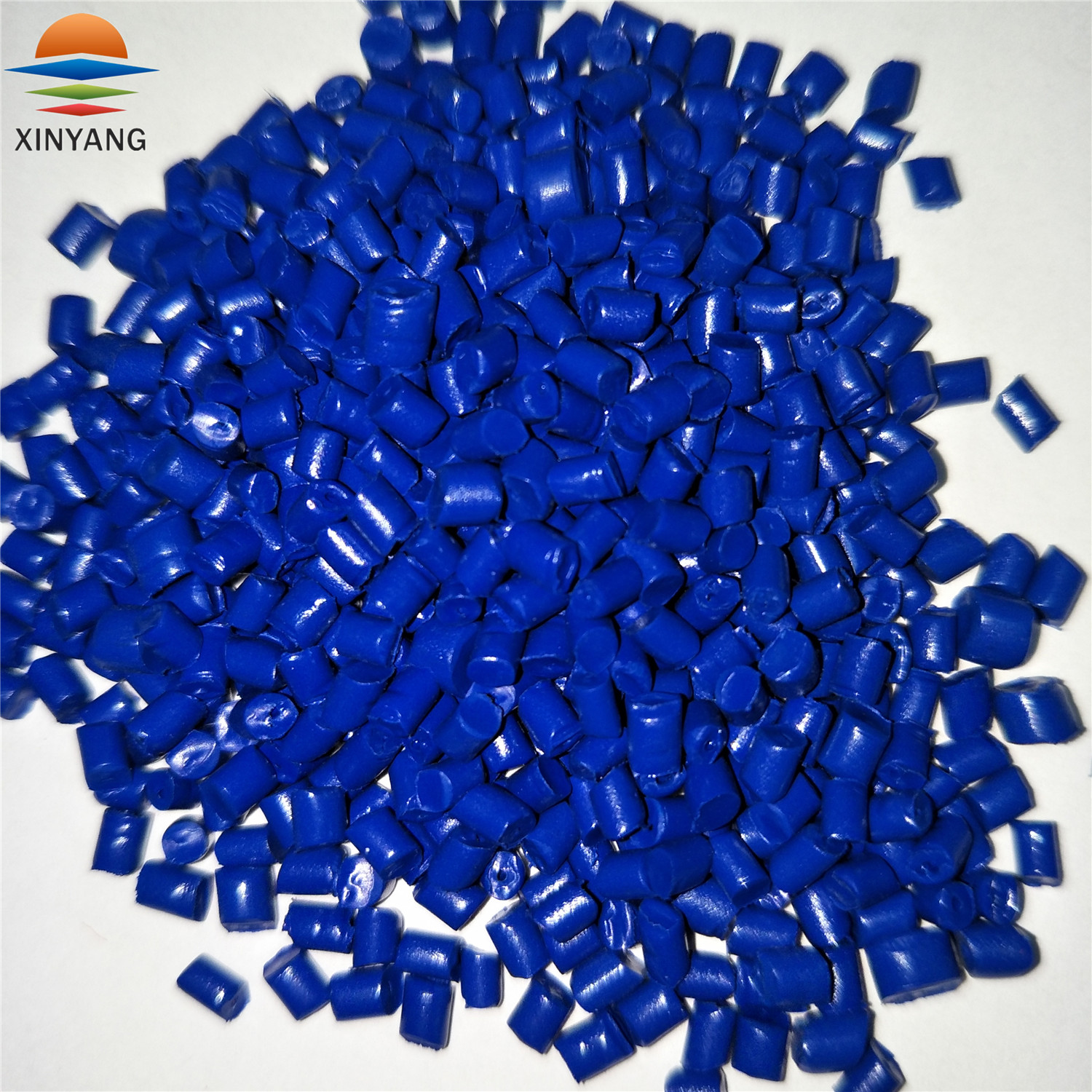

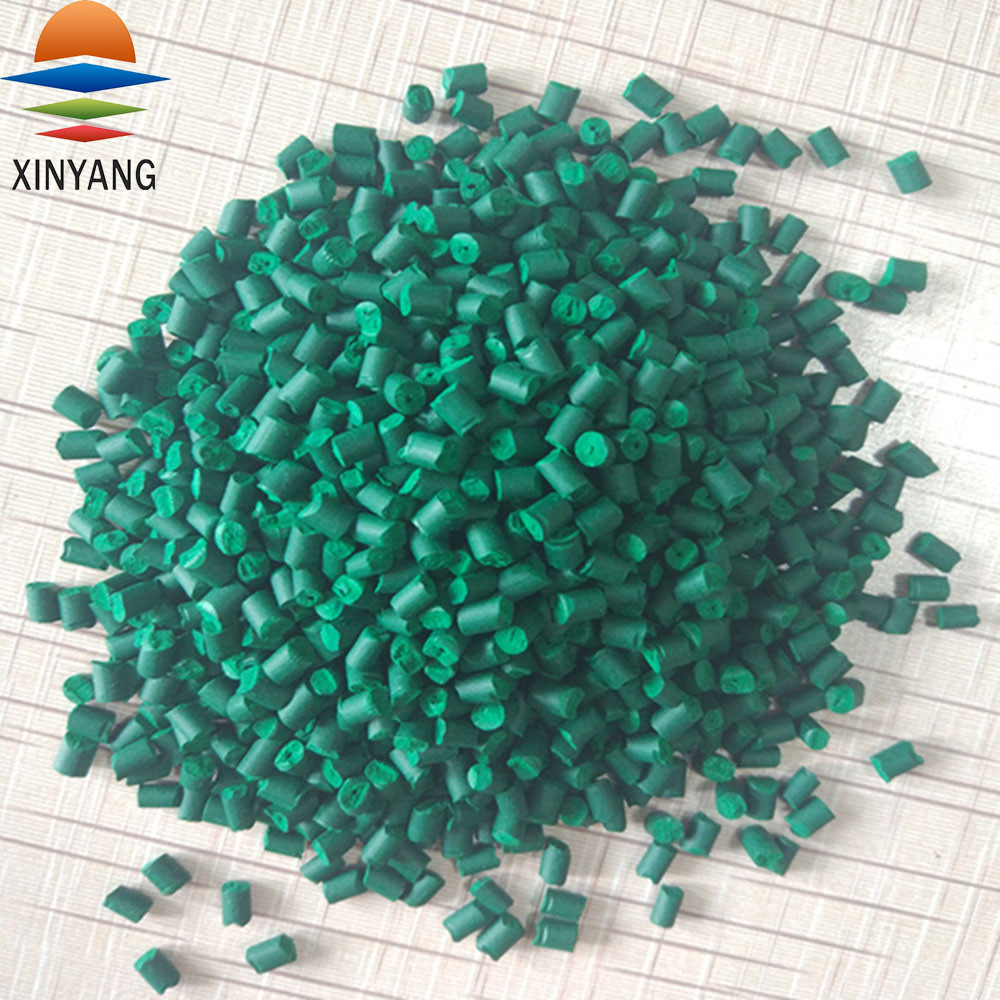

How is the masterbatch made? The resin is mixed with a coloring agent and to be granulated into a colored plastic, and then used in a molding process. Masterbatch coloring is the most commonly used plastic coloring method today. Mix the color masterbatch and resin to make plastic products. Advantages of ....

Masterbatch is a well-dispersed plastic colorant consisting of a high proportion of pigments or additives and thermoplastic resins. The selected resin has good wetting and dispersing effect on the colorant and is compatible with the pigmented material. It has the advantages of superior coloring effect, convenient autom....

The problems occurred after adding color masterbatch to injection molding is that there are stripe-like pigment strips in the product under the sun. This problem needs to be considered from two aspects: plastic physical and mechanical properties and plastic molding process: 1. The temperature of the injection mold....

The current filler masterbatch is composed of resin (the normal metabolism and secretion of plants) and various additives. The filler masterbatch has the following characteristics: 1. Increase the rigidity and weight of the filler masterbatch, and the performance of the filler masterbatch is more superior; 2. Th....

Now technology spreads everywhere, take the production equipment for example, the current production equipment is with various protection devices, plastic feeding devices have air delivery equipment, when feeding, the powder is blown away, so the masterbatch is used instead of pigment powder. In addition to this, there....

The structure and production process of plastic masterbatch Plastics are widely used in our daily lives. Many of the daily necessities, handicrafts and even some machines and equipment are made of plastic. We all know that plastic is synthetic by pouring the synthetic plastic material into the mold and finally formin....

Masterbatch is mainly used to color plastics and is an essential element in colored plastics. The coloring material is made by mixing the resin and the coloring agent and is granulated into a colored plastic, and then used in a molding process. The masterbatch makes the pigment have better dispe....

Three common classification techniques for color masterbatch: The classification method of general color masterbatch can be divided into three categories, which are classified according to carrier, color, function, etc. Now we will introduce these three categories for everyone. 1. Classification by carrier resin: ....

PP filler is made of high-quality ultra-fine calcium carbonate as the main raw material, mixed with various additives such as carrier resin and dispersant, lubricant, coupling agent and modifier, and fully mixed by high-performance twin-screw extruder and under refining, extrusion and granulation. Nowadays, PP filler ....

Extrusion: The heat resistance of the toner is poor, so the temperature must be kept low when manufacture black masterbatch. Do not allow the material to stay in the extruder for a long time. When the extruder die is clogged, the material in the barrel can also cause discoloration. Materials with poor heat res....

The filler masterbatch, that is, the polythene-filler masterbatch, is a white micro-scale calcium carbonate masterbatch made of pure raw material PE, PP or styrene resin. The calcium carbonate mesh is determined by the user's use effect and has good physical properties, dispersibility, stability, it does not affect ....

Compared with toner coloring, color masterbatch coloring has the following obvious advantages: (1) It improves the environmental pollution caused by toner flying, and it is easy to change colors during use, and it is not necessary to perform special cleaning on the extruder hopper, which is more convenient. (2) Strong ....

As the saying goes: The right effect will be better. When we choose masterbatch, we must choose the right product. When we choose masterbatch, we should pay attention to the following five aspects: First, the masterbatch with good stability should be selected. Some masterbatches have good coloring effect at that ti....

1. First, the role of the black masterbatch is to dye the plastic that needs to be dyed in black. 2. The more important parameter of black masterbatch is dispersion. Therefore, the formula of black masterbatch should be reasonable, and the production process should be strict. Otherwise, the surface of plastic prod....

It is well known that plastic-filler masterbatch can reduce the cost. Almost all plastic products use filler masterbatch, and blown film products are no exception. It is called blown film-filler masterbatch. In the process of using filler masterbatch for film blowing, we will encounter some troubles more or less. It ma....

Copyright © 2017 Qingyun Xinyang New Materials Co., Ltd. All rights reserved. 备案号:鲁ICP备15028652号-2

鲁公网安备 37142302000114号

鲁公网安备 37142302000114号