You are here:Home > News

Defoaming masterbatch is a high-efficiency defoaming masterbatch suitable for all kinds of products using ABS, PS, HIPS, PP, PE recycled plastics. The trace moisture contained in raw materials has a very serious impact on the production of plastic products. Therefore, enterprises generally use drying equipment to d....

Make it more dispersible In the production process of the color masterbatch, the pigment must be refined to improve the dispersibility and tinting strength of the pigment. The carrier of the special color masterbatch has the same plasticity as the product, and has good matching property. After heating and m....

Filler masterbatch, as its name suggests, is a filler that can replace various materials. Filler masterbatch plays a big role in promoting the rapid development of the plastics industry. Especially in the plastic products enterprises, the development process is completely inseparable from the filler masterbatch, which ....

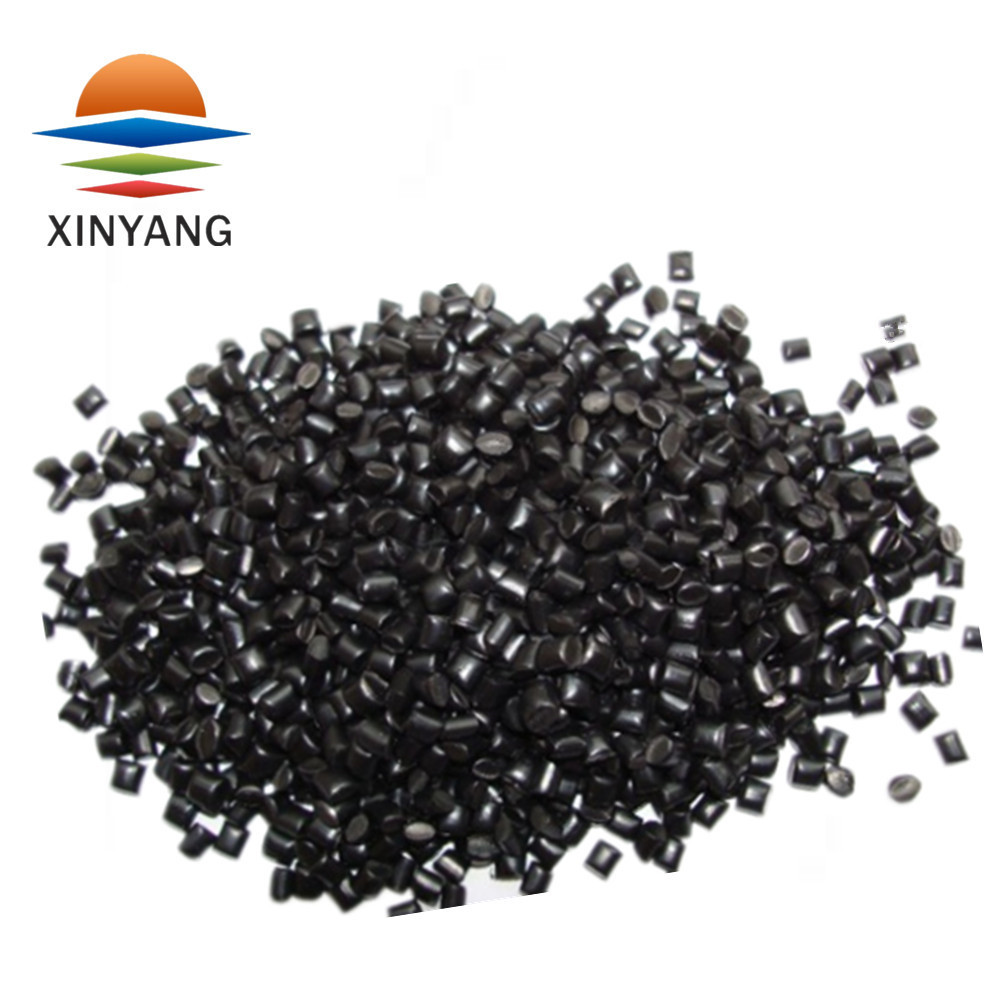

The black masterbatch is a masterbatch material produced by carbon black, carrier and additives. In recent years, it has played an extremely important role in many industries. Black gives a mysterious, high-end color feel, so the black masterbatch can add stylish label to its products. However, in some cases....

Black masterbatch also has a very important position in the molding of plastic products. Black masterbatch can be used for dyeing, for anti-aging, for conductive articles and the like. 1. What materials are the black masterbatch made up of? The materials constituting the black masterbatch are: A. car....

Xinyang will provide you six ways to identify: 1, the dispersion is high Black masterbatch is produced using carbon black. Raw carbon black is dusty, light, and fluffy, and unless it is treated with large-scale treatment, it will make the working environment dirty. Because of this, casters generall....

There are many varieties of masterbatch in China, including colored masterbatch, white masterbatch, and black masterbatch. How can we identify such a wide variety of classes? Before we understand these masterbatch products, we should first understand their different roles. Wherever we use them, as long ....

Plastic masterbatch consists of a high proportion of pigments or additives and thermoplastic resins, a well-dispersed plastic colorant. The resin chosen has good wetting and dispersing effect on the colorant and has a good compatibility with the material being pigmented. Namely: pigment + carrier + additive = m....

1. Advanced injection function masterbatch Used in cosmetic packaging boxes, toys, electrical enclosures and other advanced products. 2. Ordinary injection function masterbatch Used in general daily plastic products, industrial containers, etc. 3. Advanced blown film function masterbatch Used for b....

Today, the range of applications for injection molded parts is becoming more widespread. The injection molded parts on the market are colorful. So how do you process the injection molding? The following is a brief introduction to the three commonly used coloring methods for injection molding processing. The details....

The four recommendations for installing injection molds are as follows: 1. Preparation before installation Confirm the cooling water circuit. The depth of the screw into the plate is 1.5-1.8 times the diameter of the screw. If the screwing is insufficient, it is easy to slip and there is a risk of the mold f....

Question 1: Is the fading of plastic parts related to radiation? A: It doesn't matter! Generally, if the color is faded, the raw materials used are too small, and if the sun is directly exposed, it will be particularly easy to weather. Question 2: PP plastic parts (dark blue) faded, the staff hands are all bl....

To be comprehensive. First of all, if the calcium carbonate has a fineness of 1000 mesh and a content of less than 10% in the black masterbatch, it is a good choice for products that are not required for outdoor exposure, and the price is low. The appearance of the product is good, the carbon black is uniformly dis....

The quality of masterbatch depends mainly on the following five factors: 1. Dispersibility is better. 2. Strong coverage. 3. Liquidity is better. 4. Compatibility is better. 5. Stability should be consistent. The above five factors are provided by Xin Yang New Materilas Co. Ltd., welcome to cal....

The use of the color masterbatch is very simple, it is only necessary to mix with the resin particles according to the prescribed ratio, and it can be mixed by hand. In the operation of the equipment, the following problems should be noted: The injection molding machine or the extruder mixing chamber ge....

Copyright © 2017 Qingyun Xinyang New Materials Co., Ltd. All rights reserved. 备案号:鲁ICP备15028652号-2

鲁公网安备 37142302000114号

鲁公网安备 37142302000114号