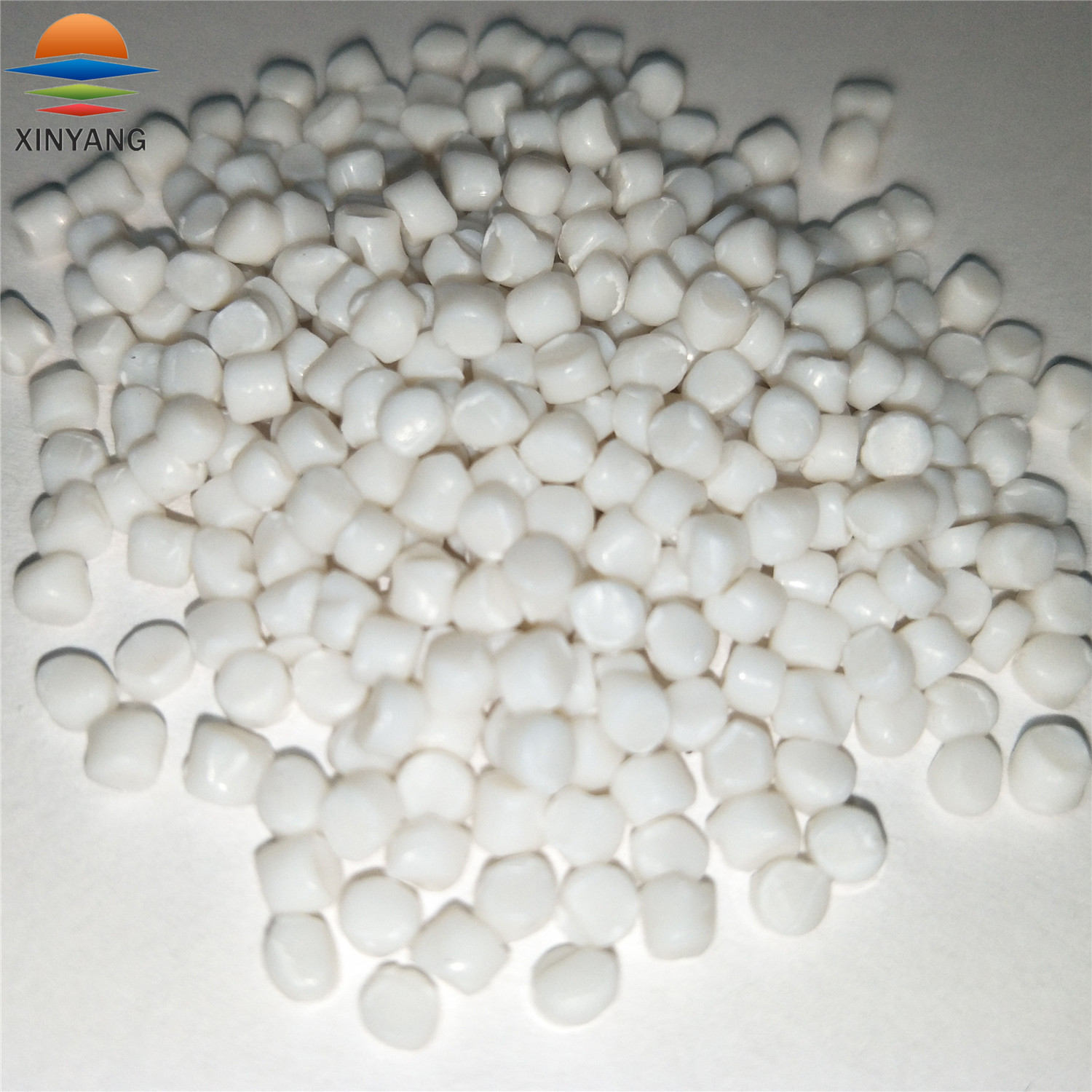

Additive Baso4 Masterbatch

- Introduce

Barium sulfate filler masterbatch uses PE/PP , styrene resin as carrier, takes barium sulfate as the main element, compound with paraffin wax and other additives, extruded by high speed mixer and then cut by air cooling.

|

BaSO4 filler masterbatch test data sheet |

|||||

|

Testing item |

Unit/raw material |

Standard value |

Tested value |

Result |

Customized |

|

powder |

NaNO BaSO4 Powder |

100% |

100% |

Qualified |

70%-80% |

|

powder finess |

Nanometer |

100nm |

100nm |

Qualified |

YES |

|

powder content |

% |

82±0.5% |

82.1% |

Qualified |

≤85% |

|

carrier |

PE+ADDITIVE |

18±0.5% |

17.9% |

Qualified |

PE/PP |

|

MFR(190℃ 5kg) |

g/10min |

8-12 |

10.5 |

Qualified |

1-30g/10min |

|

M elting |

℃ |

160 |

160 |

Qualified |

NO |

|

Density |

g/m3 |

2.4-2.7 |

2.5 |

Qualified |

NO |

|

Moisture |

% |

0.1 |

0.1 |

Qualified |

NO |

|

Transference resistance |

Grade |

7-8grade |

7-8grade |

Qualified |

NO |

|

Weather resistance |

Grade |

7-8grade |

7-8grade |

Qualified |

NO |

|

Add ratio |

% |

5%-50% |

5%-50% |

Qualified |

5%-35% |

Additive Baso4 Masterbatch advantage

High concentration pigment with bright colors

High blackness

High brightness

Uniform dispersion

High tinting strength

Excellent dispersion

Good heat-resistance

With wide application

High concentration pigment

Good dyeing property

High brightness

Testing

Packaging & Shipping

Company information

Xinyang New Materials Company has become a leader in the field of masterbatch production.

Why choose us?

We have automated the process of providing services.

We focus on quality management.

We apply mechanisms employer flexibility.

We apply differentiated pricing policy over time.

We have accurate demand forecast.

We are manufacturer and we have our own factory.

We can offer you a competitive price and high quality than other suppliers.

We can provide free sample for your testing.

We can ensure a quick delivery date.

We have various payment terms, like L/C, D/P, T/T for your choice.

We use imported testing instrument to test and measure the plastic tensile and flexural properties, SCI and SCE, the melt flow rate.

We have many kinds of masterbatches for customer's choice and also we can make the special goods under customers’ requirements.

We make sure all the products will be inspected strictly before loading. To make sure that our clients can get the satisfied and correct goods from us!

FAQ

We will make sample first and confirm with the buyer. After confirm the sample with the buyer, we will produce the formal order.

Could I get a sample for free?

Yes, you can get the sample for free, but should bear the delivery fee.

What should the buyer do before using the masterbatch?

You should confirm the percentage of appending proportion. For example, if using for film blowing with PE material, the required percentage is 4%.

What’s the normal proportion?

The normal proportion is 2% - 4%. But it is not fixed. It depends on the buyer's requirement.

How does the buyer use the masterbatch?

Mix the material and the masterbatch together by the blender mixer according to the appending proportion. If no blender mixer, it can be manual mixed.

Could you give an example for using masterbatch?

For example: Put 100kg PE material and 4kg PE masterbatch into the blender mixer. Continue the film blowing process as normal.

Certification

Contact

Ivy Lee

Overseas Sales

Qingyun Xinyang New Materials Co., Ltd

South 600 meters of Zhengjia Village, Changjia Town, Qingyun County, Dezhou, Shandong, P.R.China

Tel: (86)531 88995327

Mob/WhatsApp: (86) 18660195311

SKYPE: (86) 18660195311

WeChat: ivy897087

Email: sales1@xy-masterbatch.com

http://www.xy-masterbatch.com