Blowing Film Used MB

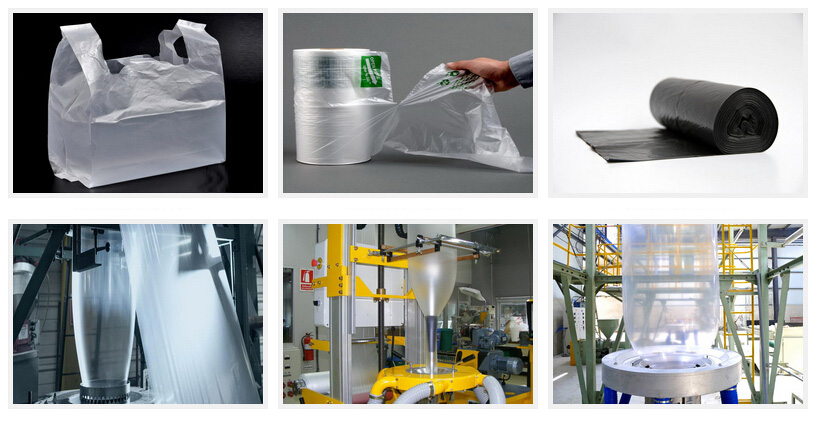

The film blowing is a kind of plastic processing method, refers to a plastic processing technology of melted and blown film with plastic resin and masterbatch. PE film processing generally uses film processing or flat extrusion processing method. The quality of film depends on material processing technology of blowing, blowing machine and plastic resin and masterbatch.

If you are using a new material for blown film, the color is clean, finished stretching. If the plastic resin are made of recycled plastic particles, when add the masterbatch to the film bags, the film may be made of uneven color, brittle and easy to break, the price of recycled plastic is low.

Our high quality blown film used masterbatch can be used for food grade films, such as a variety of fresh fruits films. Our blown film used masterbatch is applicable for most of the PE film such as general low density PE (LDPE)film or linear low density PE (LLDPE)film, HDPE film, such as commercial bags, grocery bags, and food packaging. If not with correct using of the professional film blowing machine in the process, the made membrane material may also be inferior good.

With the proper machine and processing technology, our masterbatch can help you create high quality plastic film bags.

We have color masterbatch for film coloring, filler masterbatch for plastic filling and desiccant masterbatch for absorbing moisture in recycled plastic films. For the color masterbatch, we can customize all colors. If your film bags need transparency, you can use the BaSO4 filler masterbatch, Na2SO4 filler masterbatch, CaCO3 filler etc. The transparency of BaSO4 and Na2SO4 filler is better than CaCO3 fiiler. For desiccant masterbatch, we have three kinds of desiccant masterbatch, white, gray and black desiccant, if your film is white or light color, choose the white and gray desiccant, if your film bags is black, choose the black desiccant also ok.

Qingyun Xinyang New Materials Co., Ltd.

Mr. Zhou

Email: sales1@xy-masterbatch.com

Tel: +86-0531-88995327