Extrusion Used MB

Extrusion is by heating plastic raw material and masterbatch into a viscous flow state, under the pressure effect, through the extrusion die and mold forms cross section similar to the shape of the continuum, then cooling and shaping, then cutting to form plastic products with a certain shape and size.

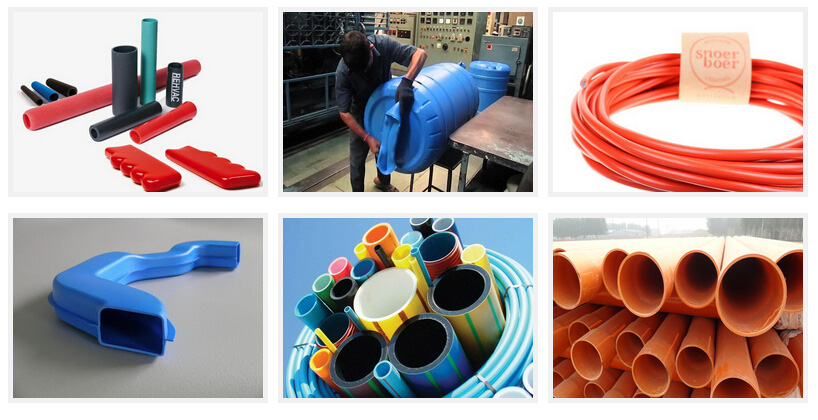

With our masterbatch you can use the plastic extrusion equipment to make the thermoplastic plastics or thermosetting material extruded into various shapes and colors, such as tube, rod, film, sheet, pipes, different shapes, wires, cables, the head pillow cover, shell, door frame, the system frame, pottery, or open sided box, the car shock absorber, the seat back, the center bracket and the arm rest, tubular membrane extrusion etc.

With the proper machine and processing technology, our masterbatch can help you create high quality plastic extrusion products.

We have color masterbatch for extrusion coloring, filler masterbatch for plastic filling and desiccant masterbatch for absorbing moisture in recycled plastics. For the color masterbatch, we can customize all colors. If your plastic extrusion parts such as pipes and cables need transparency, you can use the BaSO4 filler masterbatch, Na2SO4 filler masterbatch, CaCO3 filler etc. The transparency of BaSO4 and Na2SO4 filler is better than CaCO3 fiiler. For desiccant masterbatch, we have three kinds of desiccant masterbatch, white, gray and black desiccant, if your plastic extrusion product is white or light color, choose the white and gray desiccant, if your plastic extrusion product is black, choose the black desiccant also ok.

Qingyun Xinyang New Materials Co., Ltd.

Mr. Zhou

Email: sales1@xy-masterbatch.com

Tel: +86-0531-88995327