caco3 masterbatch

- Introduce

caco3 masterbatch details

It contains antioxidants and aging resistant agents, which can prolong the service life of the products.

|

CaCO3 filler masterbatch |

|

|

Item |

value |

|

CaCO3 content |

70-80% |

|

CaCO3 particle size |

Malvern Mastersizer 2000 |

|

MFI |

2-30g/10min |

|

density |

1.8-2.2g/m3 |

|

Pellet size of masterbatch |

3.5*3.5 mm |

|

Addition rate |

15-30% |

|

color |

white black |

|

Appearance |

granules |

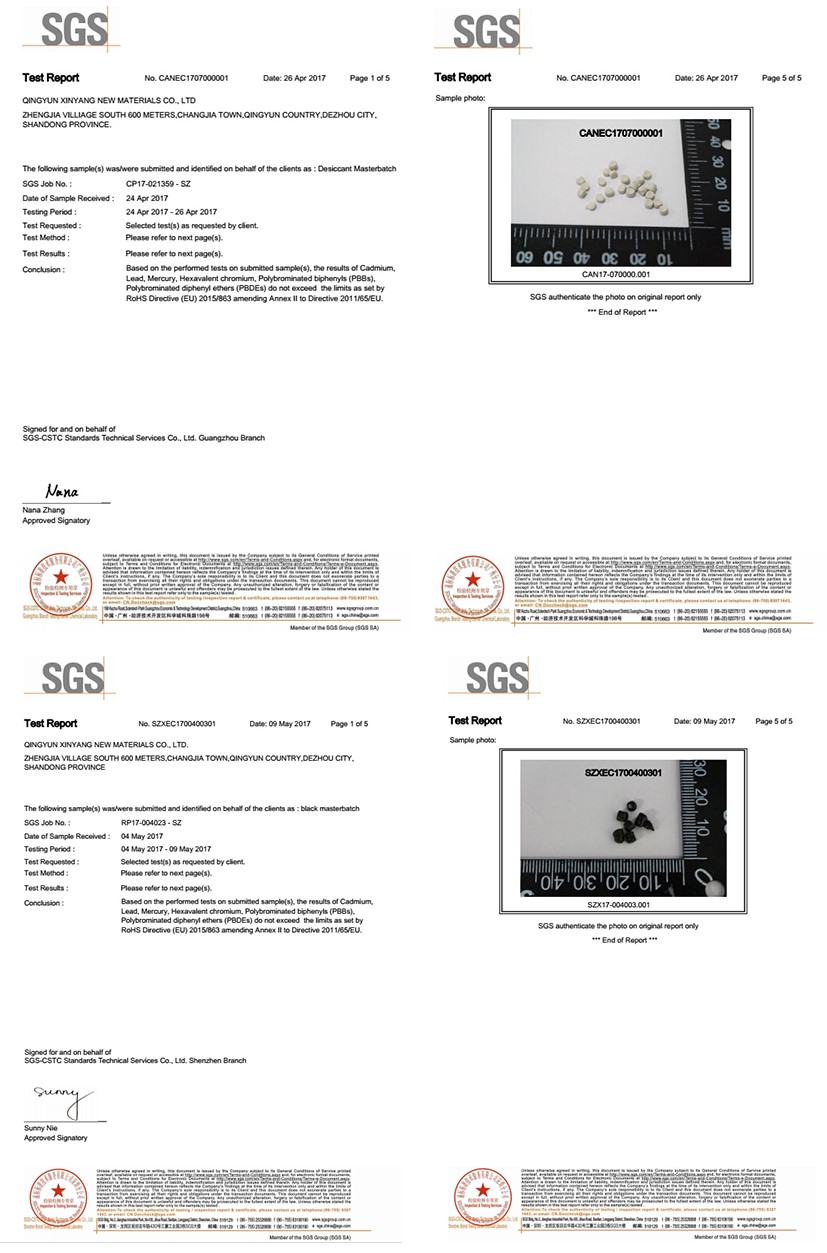

Testing

caco3 masterbatch advantage

Reducing the cost

Improving machine’s extrusion efficiency

Increases film & mold’s physical properties

Good compatibility

Reducing heat release from burning

Preventing further environmental pollution

Reduce the cost of products

Improve production efficiency

Get good economic benefits

Strengthening the rigidity of the products

Increasing the weight of the products

Rreduce the shrinkage of products

Reduce deformation caused by contraction

Good dispersibility

Good solubility with polypropylene and polyethylene

High Whiteness

Company information

In addition, five masterbatch production lines were built to produce PE, PP, PVC, PS, PC, EVA and ABS masterbatch, the annual capacity is 60000 tons. Our products are all manufactured according to the RoHS standard, and FDA certification is also available to the products of our company.

Packaging & Shipping

Why choose us?

We have high quality raw material, advanced facilities, fine procedures.

We own high productivity and fast delivery.

We have leading level R & D department.

We have strong production capacity, high speed delivery.

We provide good quality product with competitive price.

We have experienced marketing manager.

We have professional design department.

We provide excellent after-sales service.

We will do our best for the customer as long as you choosing us.

We promise to solve all the problems during trading process.

We promise our quality and the products will be approved by your side.

We will regularly track level of customer satisfaction.

We have automated the process of providing services.

We focus on quality management.

We apply mechanisms employer flexibility.

We apply differentiated pricing policy over time.

We have accurate demand forecast.

FAQ

What should the buyer do before using the masterbatch?

You should confirm the percentage of appending proportion. For example, if using for film blowing with PE material, the required percentage is 4%.

What’s the normal proportion?

The normal proportion is 2% - 4%. But it is not fixed. It depends on the buyer's requirement.

How does the buyer use the masterbatch?

Mix the material and the masterbatch together by the blender mixer according to the appending proportion. If no blender mixer, it can be manual mixed.

Could you give an example for using masterbatch?

For example: Put 100kg PE material and 4kg PE masterbatch into the blender mixer. Continue the film blowing process as normal.

How do the customers customize color?

Customers offer to us the sample of color sheet as the required color. We make our own samples according to customer's sample sent to us.

Certification

Contact

Ivy Lee

Overseas Sales

Qingyun Xinyang New Materials Co., Ltd

South 600 meters of Zhengjia Village, Changjia Town, Qingyun County, Dezhou, Shandong, P.R.China

Tel: (86)531 88995327

Mob/WhatsApp: (86) 18660195311

SKYPE: (86) 18660195311

WeChat: ivy897087

Email: sales1@xy-masterbatch.com

http://www.xy-masterbatch.com

Copyright © 2017 Qingyun Xinyang New Materials Co., Ltd.