Color masterbatch details

Customized production is accepted. We offer you the most cost-effective product according to the requirement or the actual production situation of the customers.

|

Color masterbatch test data sheet

|

|

Appearance

|

3*3mm round granule, bright and smooth surface

|

|

Appearance

|

granules

|

|

Granule diameter

|

2.5*3.5mm

|

|

Application

ratio

|

3-4%

|

|

Carbon black

concentration

|

40%

|

|

Carbon black

content

|

30%

|

|

Carbon black

content

|

45%

|

|

Carbon type

|

N330/N326

|

|

Carrier

|

PE

|

|

Chromatic

aberration ΔE

|

≤0.5

|

|

Coloring

Strength

|

120-130%

|

|

Content of

carbon black

|

40%

|

|

Density

|

1.22g/cm3

|

Color masterbatch advantage

Containing high concentration pigment

High darkness which makes your product black enough

High brightness that makes your product bright enough

Showing better dispersing and stability performance

Suitable for PE/HDPE/LDPE/PP/ABS/PS/HIPS/PVC/EVA

Adopting high quality carbon black with steady properties

Using the organic toughening dispersant

Processed and modified by special technology

Using the optimized dispersant which helps the carbon black to spread

Company information

Our company is qualified as a supplier of numerous domestic and

international companies, and we have won a high praise from foreign and

domestic customers.

Packaging & Shipping

Why choose us?

We have modern production and testing equipment.

We have high quality raw material, advanced facilities, fine procedures.

We own high productivity and fast delivery.

We have leading level R & D department.

We have strong production capacity, high speed delivery.

We provide good quality product with competitive price.

We have experienced marketing manager.

We have professional design department.

We provide excellent after-sales service.

We will do our best for the customer as long as you choosing us.

We promise to solve all the problems during trading process.

We promise our quality and the products will be approved by your side.

We will regularly track level of customer satisfaction.

We have automated the process of providing services.

We focus on quality management.

We apply mechanisms employer flexibility.

FAQ

What’s the normal proportion?

The normal proportion is 2% - 4%. But it is not fixed. It depends on the buyer's requirement.

How does the buyer use the masterbatch?

Mix the material and the masterbatch together by the blender mixer according to the appending proportion. If no blender mixer, it can be manual mixed.

Could you give an example for using masterbatch?

For example: Put 100kg PE material and 4kg PE masterbatch into the blender mixer. Continue the film blowing process as normal.

How do the customers customize color?

Customers offer to us the sample of color sheet as the required color. We make our own samples according to customer's sample sent to us.

Is there other way to get the desired color?

We send our sample to customer for test. We produce according to orders after the sample got approved by the customers.

Do we provide free sample of the products?

Of course, please feel free to tell me your specific requirements, and then we will make the corresponding customized sample to you.

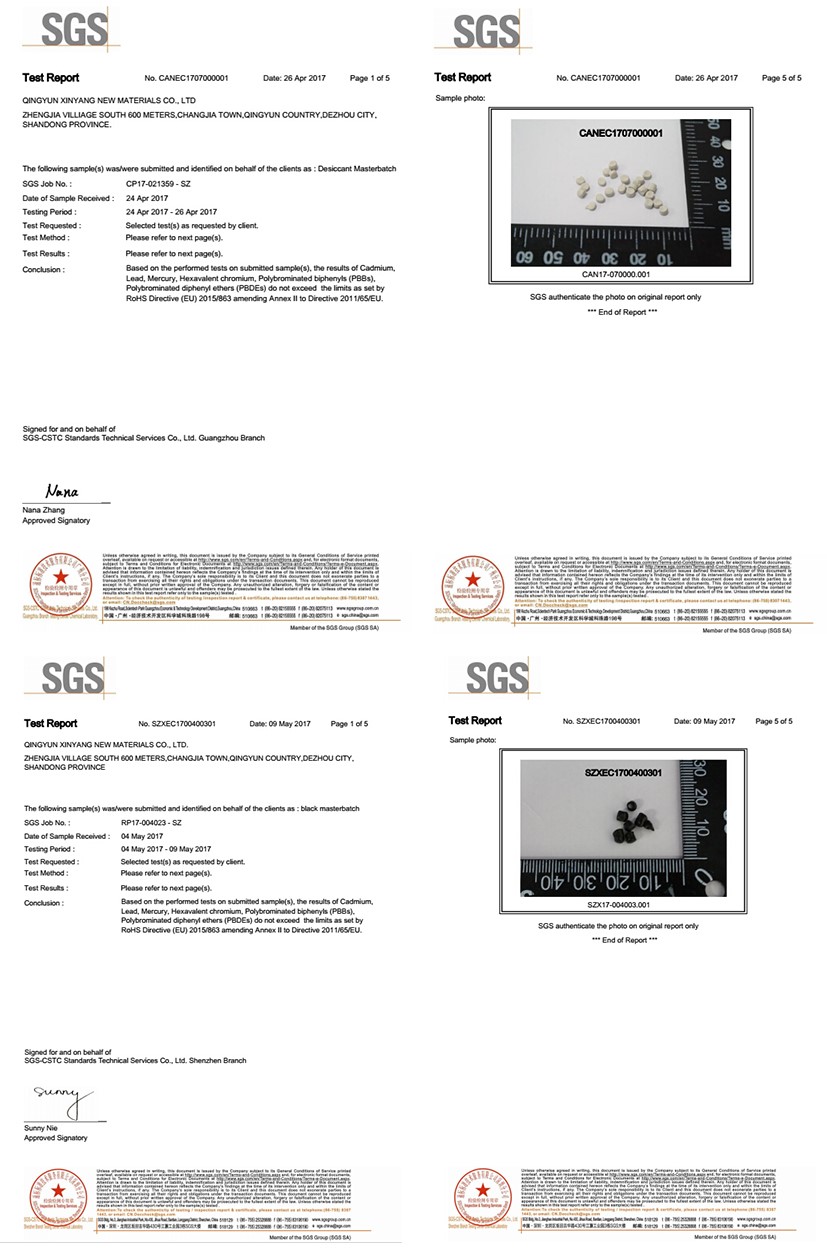

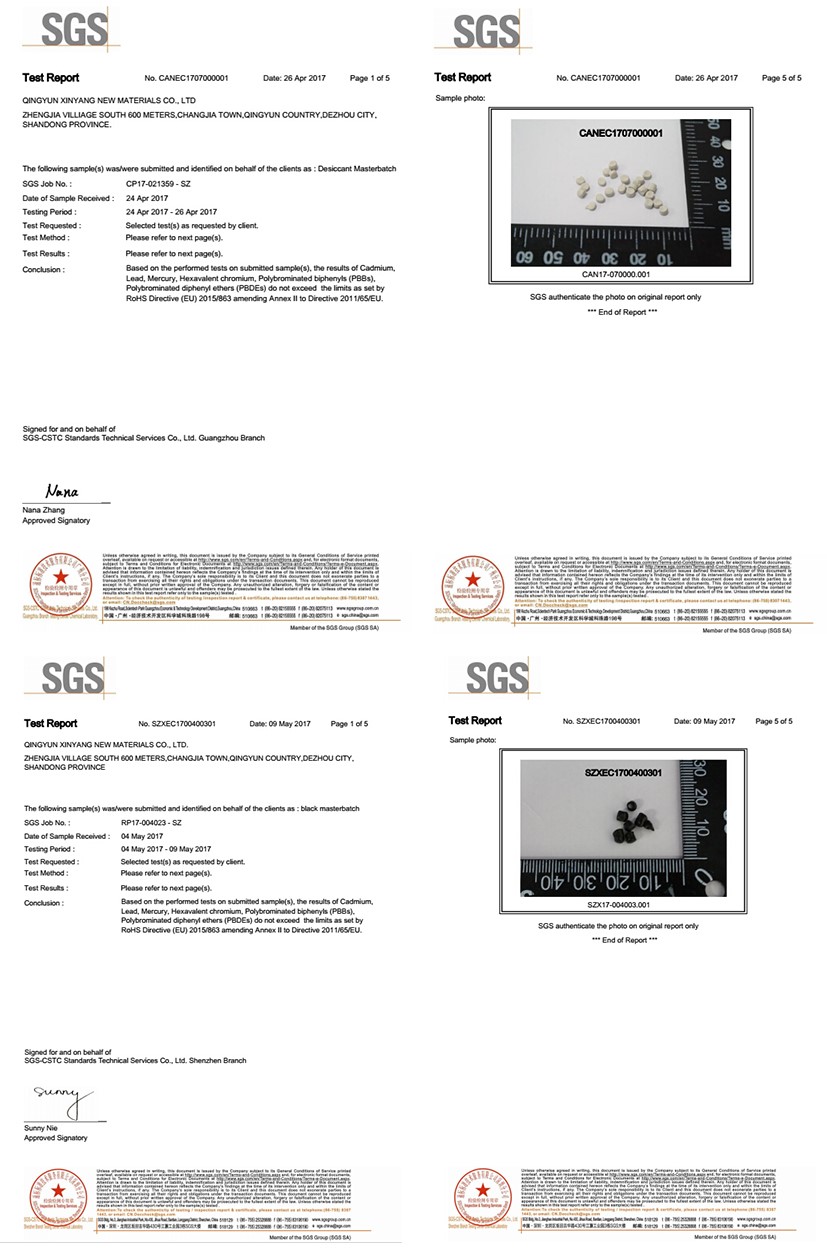

Certification

Contact

Ivy Lee

Email: sales1@xy-masterbatch.com

Tel:+86-0531-88995327

Mobile:+86-18660195311

Whatsapp: +86-18660195311

Address: 600 meters south of Zhengjia Village, Changjia Town, Qingyun County, Dezhou, Shandong, P.R.China

Color masterbatch application

Injection Molding (Box, Containers, Chairs, Crates, Buckets, Battery, cases, Hangers, etc.)

Injection Molding (Automotive, Electronic, Construction, House wares, Furniture, Toys, etc.)

Extrusion Molding (Sheet, Pipe, Wire & Cable, etc.)

Film (shopping bags, casting film, multilayer film, etc.)

Fiber (Carpet, Textiles, Upholstery, etc.)

Blow Molding (Medical & Cosmetic Container, Lubricant & Paint Container, etc)

鲁公网安备 37142302000114号

鲁公网安备 37142302000114号