Pet plastic raw material desiccant masterbatch

- Introduce

● Product Introduction:

Pet plastic raw material desiccant masterbatch by shandong factory Gray 1 is produced by our factory,Defoaming masterbatch is also called the Desiccant Masterbatch or the Moisture Absorber. It’s suitable for the production of all the PE/PP recycled plastic products. It has the very serious impact to the plastic products if the raw material contained the trace water, so the factory usually use the drying equipment to dry the plastic. It is a big waste both for energy and manpower, and increased the cost of the products. If you use the defoaming masterbatch, just add it directly to the raw material, no need to change any produce process. It helped to remove the bubble, moire, crack, spots of the plastic products that caused by water.

Desiccant Masterbatch |

|

Color |

White/Grey/Black |

Carrier |

PE/PP |

Filler |

Calcium Oxide |

CaO content |

75%-88% |

Water absorption |

≤20 |

Melting point(℃) |

110-150 |

MFI(g/10 min) |

0.5-50 |

Density(g/cm³) |

1.5-2.1 |

Volatility |

1.5±0.5% |

Time to keep in mixture |

24 hours |

Light fastness |

≥5 |

Heat resistant |

≥5 |

Migration resistant |

≥4 |

Technical Specification |

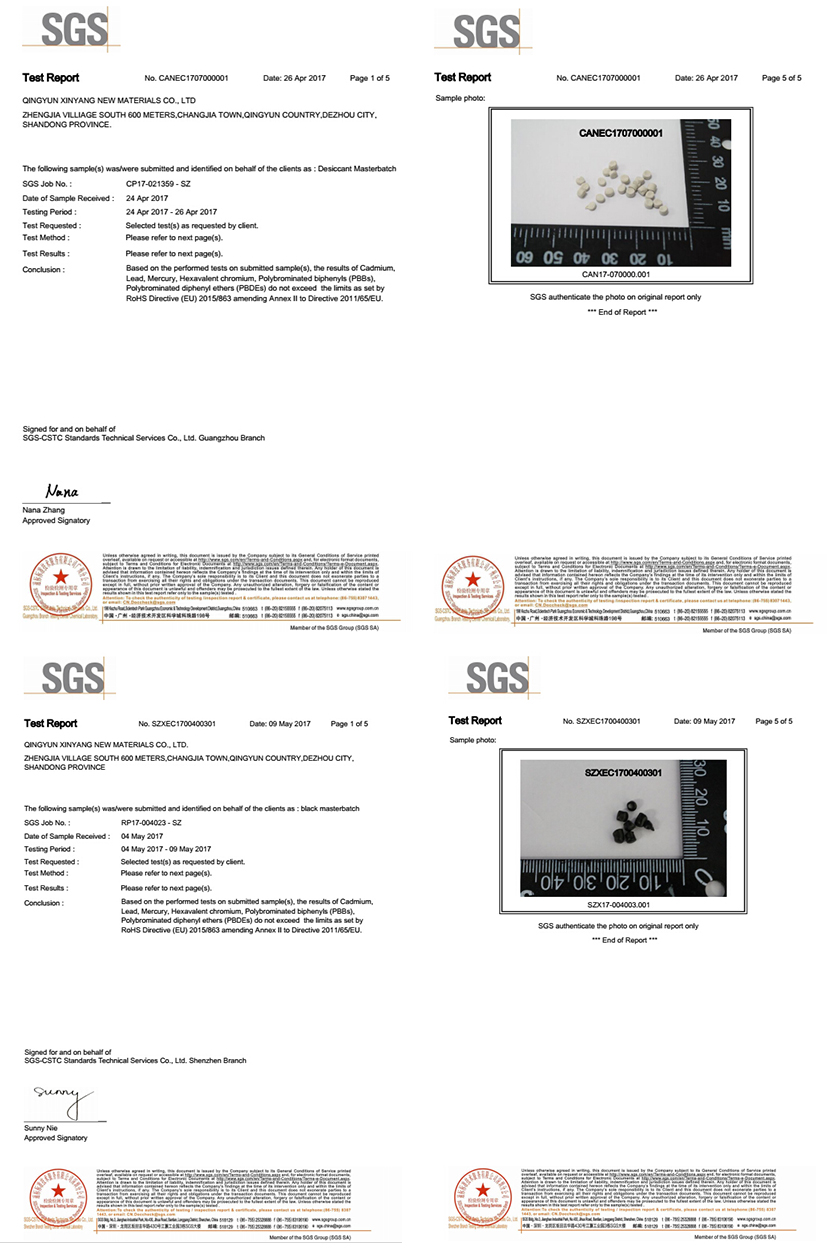

SGS Certificate |

Package |

Vacuum packing,1kg/2.5kg/5kg |

Add Ratio |

Recommend to add 2%-10% |

● Product Advantage :

PS, HIPS masterbatch use ratio and methods:

The master batch and raw material resin ratio of 1: 10-50 (based on the specific requirements of the product may be) by mixing (after drying if necessary) can be used.

Fourth, the advantages of using ABS masterbatch

1, to ensure that the pigment dispersion to achieve the desired effect, and to achieve the stability of different batches of colored products, color;

2, to maintain the chemical stability of pigments and other additives, the plastic material to reduce heat degradation;

3, easy to operate, clean environment, significantly reduce labor

The advantage of Masterbatch is dust free, easy flowing, cheaper than compound cost and consumes very little warehouse space. The disadvantage of Masterbatch is that it has poorer uniformity of color.

● Product Application:

It could be used directly by mixing the masterbatch and the damp plastic raw material uniformly. For the blow molding, the adding ratio is 1%~2%. For the sheet or injection molding, the adding ratio is 2%~5%. The specific adding ratio is decided by the water content in the plastic.

Widely used in mold products,bag products,sheet products and injection molding products.

● Our service:

1 High quality and competitive price

2 Quick door to door service

3 Advanced testing equipment

4 Good after-sale service

● OEM:

1.COLOUR MATCHING

Based on important datas, such as application process, base resin, desired letdown ratio, chemical resistance and heat resistance specifications, light fastness conditions with the type of end product exposure and food grade approval requirements from the customers etc

2.TECHNICAL SUPPORT

The manufacturing lines of the company are backed by state of the art testing and controlling facilities in a laboratory equipped for research and development work

3.AFTER-SALES SERVICE

● QC:

● Attention:

1. Avoid damped before using.

2. Once mixed with raw material, use it in time.

3.The masterbatch cannot be heated or dried together with the damp plastic in case of some bad influence of the quality for the products.

4.Check and confirm if the package was well sealed. Once opened, use it ASAP or heat sealed for the balance.

● FAQ:

Q1:Do we provide free sample of the products

A: Of course,please feel free to tell me your specific require,and then we will make the corresponding customized sample to you .

Q2: What is the shipping terms?

A:FOB Qingdao,others accepted

Q3: How about your payment?

A:T/T,L/C,western union.

Q4:What kind of plastic do our masterbatch fit?

A:Perfectlysuit:PE/PP/PC/ABS/PET/HIPS/GPPS/PA/PMMA/AS/POM/PU/TPE

Q5:What is the packing?

A: Net weight:25kg/bag.

Paper plastic compound bag.

Storage:Please store in dried space.

● Packaging And Storage:

Vacuum packaged,1kg/2.5kg /5kg per bag,avoding the package broken and keep always well sealed,store in the dry place,avoiding sun exposure or the rain.

Delivery Detail:Shipped in 7 days after payment

● Certifications:

● Factory:

Qingyun Xinyang plastic masterbatch Co. Ltd is founded in 2002, registered capital of 5 million, 50 million fixed assets, covers an area of 30 thousand square meters.

The company is located in northern Shandong, the hinterland of the Yellow River Delta, the southwest coast of the Bohai Bay, North Bohai, Tianjin port and Qingdao port adjacent to convenient transportation and smooth transportation.

Since the establishment of the company, the introduction of advanced management concepts, the company has formed an annual output of 20000 tons of black masterbatch, defoaming Masterbatch color masterbatch and white 10000 tons, 10000 tons, 5000 tons of polyethylene wax filled masterbatch, the production capacity of 4000 tons. Product sales, domestic and exported to the United States, Venezuela, South Africa, Saudi Arabia, Southeast Asia, the Middle East, Africa, Europe and many other countries and regions.

● Transport:

Provide EXW,FOB,DDP,DDU shipping terms.

● Payment:

Support T/T Deposit , Balance against bill of lading,Alibaba Trade Assurance ,Letter of Credit and other paymentterms.Shipped in 7 days after payment.

● Contact Us:

Mr. Zhou

Tel:+86-0531-88995327

Address:Zhengjia Villiage South 600 meters,Changjia Town,Qingyun country,Dezhou City, Shandong Province.If you're in need of our products to help with your business, welcome to contact us. We are a professional manufacturer of various masterbatches, offering you the best quality products with good performance and competitive price.

next page:The Newest Reliable Quality injection moulding color masterbatch