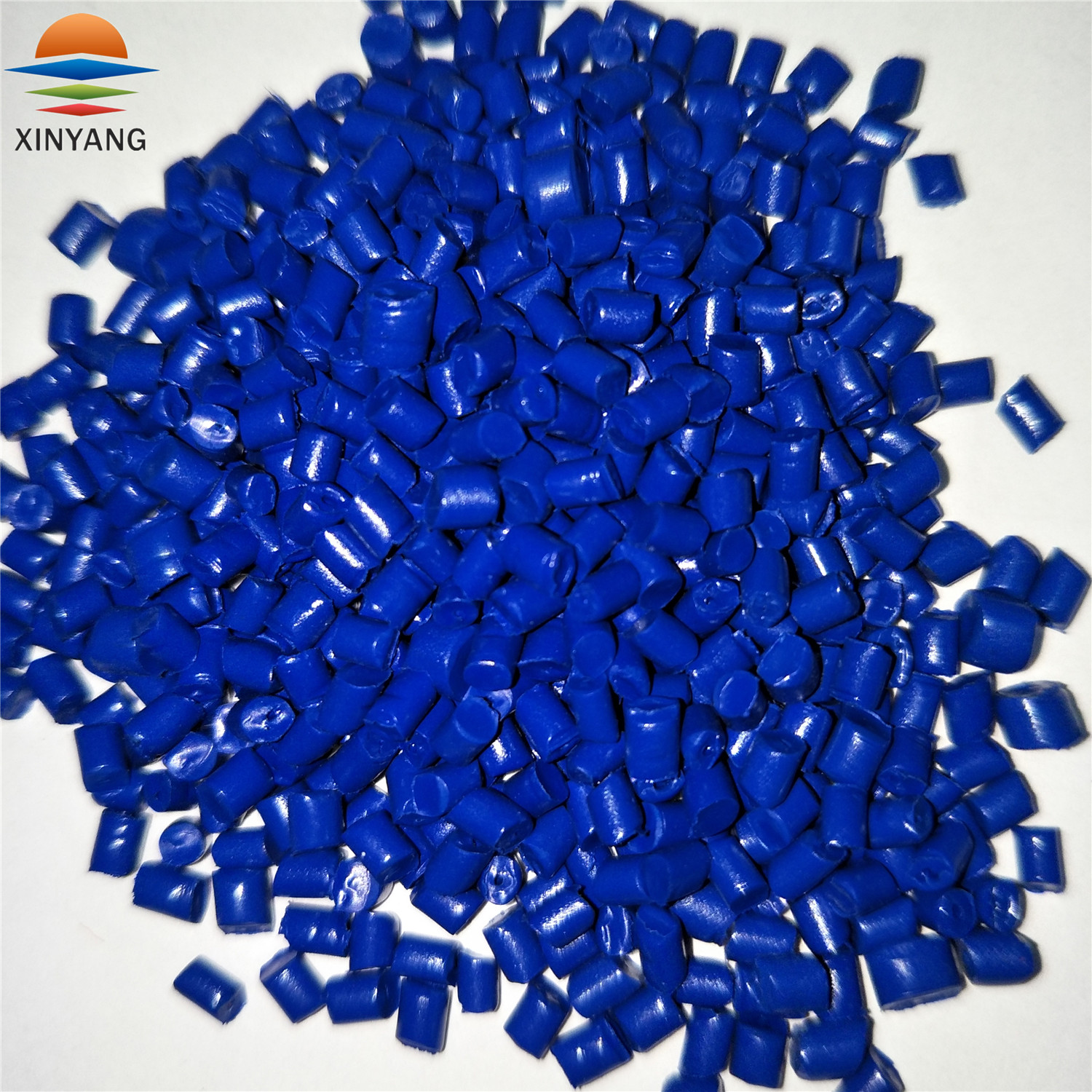

Woven bag special used color masterbatch

- Introduce

Detailed description

Masterbatch is an aggregate obtained by uniformly

loading a super-constant pigment into a resin.

Color masterbatch is a new type of coloring agent

for coloring materials, also known as Pigment Preparation. It consists of three

basic elements: pigment or dye, carrier and additive. It is an aggregate

obtained by uniformly loading a super-constant pigment or dye into a resin. It

can be called PigmentConcentration, so the tinting strength of masterbatch is

higher than the pigment itself.

Basic ingredients:

1. Pigment or dye

Pigments are further divided into organic pigments

and inorganic pigments.

Commonly used organic pigments are: phthalocyanine

red, phthalocyanine blue, phthalocyanine green, fast red, macromolecular red,

macromolecular yellow, permanent yellow, permanent violet, azo red and other

commonly used inorganic pigments: cadmium red , cadmium yellow, titanium

dioxide, carbon black, iron oxide red, iron oxide yellow, etc.

2. Carrier

It is the matrix of the masterbatch. The special

color masterbatch generally selects the carrier resin same as the resin of

making the plastics, since the compatibility between the two is the best, but

the fluidity of the carrier is also considered.

3. Dispersant

The pigment is uniformly dispersed and no longer

aggregates. The melting point of the dispersing agent should be lower than that

of the resin, have good compatibility with the resin, and have good affinity

with the pigment. The most commonly used dispersants are: polyethylene low

molecular waxes, stearates.

4. Additives

Such as flame retardant, brightening,

antibacterial, antistatic, anti-oxidation and other varieties, unless the

customer asks, in general, the color masterbatch does not contain the above

additives.

General purpose masterbatch and special masterbatch:

Dedicated color masterbatch: According to the

plastic type specified by the user, this masterbatch selects the carrier resin

same as the resin for making customer’s plastic. For example, PP color

masterbatch and ABS color masterbatch respectively use PP and ABS as carriers.

Universal color masterbatch: This masterbatch also

takes certain resin (normally low melting point PE), but this masterbatch can

be applied to the coloration of other resins than its carrier resin.

The universal color masterbatch is relatively

simple and convenient, but has many disadvantages. It is recommended that you

use the special color masterbatch.

Why are many companies not producing universal color masterbatches?

Most formal color masterbatch companies in the

world generally do not produce universal color masterbatches.

There are many disadvantages to the universal

color masterbatch. In fact, the general purpose of the universal color

masterbatch is very narrow, and the technical indicators and economic benefits

are also poor. The specific performance is as follows:

1. Poor predictability of coloring effect

The color masterbatch is used for coloring, and

the pigment of the universal color masterbatch exhibits different colors in

different plastics, so the coloring effect is less predictable.

2. Affect other properties of plastic products

In particular, it affects the strength, and the

product is easily deformed and twisted, which is more obvious to engineering

plastics.

3. Higher cost

In order to be 'universal', the universal color

masterbatch often uses a higher heat-resistant grade of pigment, resulting in

waste.

In addition to coloring, can the color masterbatch also have the functions of flame retardant, brightening, antistatic, anti-oxidation and anti-ultraviolet rays?

The color masterbatch can have several of these

functions at the same time, if the customer requires.

Sometimes, although the customer does not ask for

it, the color masterbatch company will advise the user to add some additives

depending on the needs of the product, such as adding certain additives such as

brighteners to the color masterbatch. Of course, this will increase the cost of

the product.

Heat resistance

The heat resistance grade of the special color

masterbatch is generally compatible with the plastic used for the product, and

can be used with confidence at normal temperature. Only in the following cases

will cause different degrees of discoloration, first, the temperature is beyond

the normal range; Second, the downtime is too long.

What is the difference between granulation coloring and masterbatch coloring?

Masterbatch coloring has the following advantages

over granulation coloring:

1. Coloring and product processing are completed

once, avoiding the heating process of granulation coloring on plastics, and is

beneficial to the quality of plastic products.

2. The production process of plastic products is

simplified.

3. Can save a lot of power

Will the product colored with the masterbatch not fade?

There is no product that does not fade, and

products that use color masterbatch may still fade, but the fade degree of

product is different for different grades, some are more obvious, and some are

hard to detect.

1. how to use color masterbatch?

The use of the color masterbatch is very simple,

it is only necessary to mix with the resin particles according to the prescribed

ratio, and it can be mixed by hand.

Pay attention to the following issues during the

operation of the device:

1.1. The mixing chamber of the injection molding

machine or extruder generally has multiple temperature zones, and the

temperature near the feed dropping port should be slightly higher. This is to

make the color masterbatch melt quickly and mixing evenly as soon as possible

with the plastic resin after entering the mixing chamber, which is beneficial

to the color masterbatch in a well dispersed state in the product.

1.2. Appropriate application of back pressure to

the injection molding machine can improve the mixing effect of the screw and

facilitate the dispersion of the pigment. The side effect of applying the back

pressure is to slow down the injection speed.

1.3. Increasing the temperature of the die of the

extruder can increase the brightness of the product.

2. How to determine the proportion of color masterbatch used?

The basis for determining the use ratio of the

masterbatch is to obtain a satisfactory coloring effect. As long as the surface

of the product is uniform in color and there are no streaks and spots, it can

be recognized. The proportion of color masterbatch can be selected as follows:

1:100 Unless

the mixing of the equipment is very good, it is prone to uneven pigment

dispersion. It is generally not recommended for customers to use this ratio.

However, some customers are particularly eager to

use this proportion of color masterbatch due to price pressure. For the sake of

customers, they also produce such a low proportion of concentrated color

masterbatch, and the dispersibility of the pigment can generally meet the

requirements.

1:50 This is used for coloring general plastic

products, mostly for PE and PP color

masterbatch.

1:33--1:25 For PO products with higher coloring

requirements, lower coloring requirements or general ABS products

1:20 This

is used in advanced plastic products, including PO and ABS, which can be widely

used in injection molding, blow molding, spinning and other processes.

1:20 or more Generally used for coloring

high-grade cosmetic containers, mostly used in small injection molding machines

3. How to calculate the cost of using color masterbatch?

The weight of the color masterbatch itself should

be deducted when calculating the cost of coloring the masterbatch.

For example: When 2 kg of color masterbatch is

added to 100 kg of plastic resin, the total weight is already 102 kg. Assuming

the resin price is 1.5 usd/kg, the color masterbatch price is 3 usd/kg.

The cost of using a color masterbatch in 102 kg

plastic product is:

2 kg × (3usd / kg -1.5usd / kg) = 3 usd

The cost added to each 100 kg of plastic product

due to the use of color masterbatch is:

3 usd / 102 kg × 100 kg = 2.94usd

4. Will the use of color masterbatch increase product cost?

In most cases that is true. In some cases,

however, coloring with color masterbatch is more economical than coloring with

toner, because colorists can achieve higher color pigment coloring through a

combination of several lower-priced pigments.

Also consider the following two phenomena:

1. In many cases, the choice of pigments used by

plastics manufacturers in color matching is not the most economical, and

because of the lack of familiarity with pigments, it is very common to repeatedly

test the color and cause waste of manpower and materials. This problem does not

exist with the color masterbatch used.

2. The products colored with the masterbatch and

the products colored with the toner are completely different in grade, and the

selling price is also higher. The selling price is often higher than the cost

increased by using the color masterbatch, so the color masterebatch can create

"profit" instead. From this perspective, in some cases, coloring with

color masterbatch is more economical than coloring with toner.

5. Does the color masterbatch need to be dried before use?

Color masterbatch do not need to be dried under

normal conditions and can be used directly. However, except for ABS and NY

masterbatch, they should be dried according to conventional techniques.

6. How long is the color masterbatch's shelf life?

Color masterbatch can be stored for a long time.

The pigment in the color masterbatch is dispersed

and fixed in the carrier resin, and is in a closed state, and the quality does

not change even if it is stored for a long period of time. But should be stored

in a dry, cool environment

7. Can you use several different color masterbatch to prepare the color?

In general, companies often use several color

masterbatches to formulate specific colors for small-volume customers.

However, in the absence of the guidance of the

company's technical staff, the customer can not make their own decision to use several

color masterbatch together, and can not mix the color masterbatch produced by

different companies, in order to avoid loss caused by incompatibility.

8. Does the use of color masterbatch affect other properties of the product?

Some pigments have an effect on the flame

retardant effect of the product. When used in flame retardant products, pls

inform the masterbatch manufacturer of this.

9. Does the mold have any effect on the use of the masterbatch?

In order to fully display the coloring effect of the masterbatch, the mold must have a corresponding quality, especially the surface must be very smooth.

Pigment performance

1. Heat resistance

PVC, PE pigment temperature resistance 160-180

degrees Celsius

ABS, PS pigment temperature resistance 250-280

degrees Celsius

PP, PA, PET pigments are more than 280 degrees

above temperature

It is generally required that the heat resistance

time of the pigment is 4 to 10 minutes. Generally, the higher the use

temperature, the shorter the heat resistance time. Indigo blue pigment

temperature 325 degrees Celsius, 10 minutes discoloration

2, mobility

The migration resistance of pigments means: When colored

plastic products contact with other solid, liquid, gas and other materials or

work in a specific environment for long time, may have physical and chemical

effects with the above substances, expressed as pigments from plastic interior

migrating to the free surface of the article or migrating to an adjacent

plastic or solvent.

Migration resistance rating standard

Level 1 Level 2 Level 3 Level 4 Level 5

Severe migration, significant migration,

migration, slight migration, no migration

3. Most of the inorganic pigments have good light

resistance.

4. Weather resistance refers to the color

stability of pigments under natural conditions.

5. Titanium dioxide is divided into: anatase (A)

titanium dioxide rutile (R) titanium dioxide

Titanium dioxide can improve hiding power,

tolerance, fading resistance, etc.~~~

When the concentration of titanium dioxide is low,

the whiteness of PP increases with the increase of its content. When the

concentration exceeds 1.5%, the whiteness no longer rises, from 1% to 8%, the

whiteness increases by 2.8%, which indicates that when the concentration

exceeds a certain concentration, increasing the amount of titanium dioxide does

not improve the whiteness. In order to further increase the whiteness, a fluorescent

whitening agent can be used, and the tinting strength of the titanium white

powder can be significantly improved by using only a small amount of the

fluorescent whitening agent.

Titanium dioxide

Titanium dioxide allows plastics to effectively

scatter visible light to impart whiteness, brightness, and opacity.

The concentration of titanium dioxide in PP ABS is

1%; in PVC, it is 4%; as the amount of titanium dioxide increases, the hiding

power increases gradually, and when the concentration is greater than 8%, it

tends to balance.

In general, the finer the titanium dioxide

particles, the higher the tinting strength and the stronger the hiding power.

6. Cadmium yellow has strong tinting strength,

excellent light and weather resistance, no migration, no bleed (toxic paint).

This product can be used as a yellow coloring agent for plastics. It has bright

colors, excellent light resistance, heat resistance, solvent resistance, water

resistance and alkali resistance, but it is not resistant to acid, and the

coloring and hiding power is not strong.

7. Ultramarine has the function of whitening and

coloring, which can remove the yellow color in the plastics.

Any questions further, pls contact:

Ivy Lee

Tel: (86)531 88995327

Mob/WhatsApp: (86) 18660195311

SKYPE: (86) 18660195311

WeChat: ivy897087

Email: sales1@xy-masterbatch.com