Drying Masterbatch

- Introduce

Desiccant masterbatch can be widely used in PP/PE recycled plastic production. Calcium oxide is the main raw material.

|

Desiccant masterbatch |

|

|

Items |

value |

|

Appearance |

granular |

|

Color |

White or grey or black |

|

Calcium Oxide content |

70-80% |

|

Carrier |

PE/PP |

|

Water absorption |

20% |

|

Moisture absorbent weight |

20~25±1,0% |

|

MFI(230°C/10min) |

5~10g/10min |

|

Melting Point (°C) |

120℃ |

|

Density(g/m?) |

1.4+/-0.1g/m? |

|

Volatility |

1.5+/-0.5% |

|

Pellet size of Masterbatch |

2.5micron |

|

Addition Rate(%) |

2-5% |

|

Packing (Net weight) |

25 Kg/ bags Vacuum packaging |

|

Time to keep in Mixture |

20 to 48 hours |

Drying Masterbatch Advantage

Perfect diffusing

Less effect on products glossing and coloring

Good corrosion resistance

Powerful water absorbing up to its weight 20%

Non-toxic and environment-friendly

No hurt on worker

Testing equipments

Company information

Xinyang New Materials Company is a professional manufacturer of masterbatch. With the advanced test equipments, skilled workers, experienced technician, strong manufacturing capability, now our company enjoys high reputation for its excellent performance, reliable quality and reasonable price, we hold the tenet of “quality first, customer first, service best.”

Packaging & Shipping

Why choose us?

We have modern production and testing equipment.

We have high quality raw material, advanced facilities, fine procedures.

We own high productivity and fast delivery.

We have leading level R & D department.

We have strong production capacity, high speed delivery.

We provide good quality product with competitive price.

We have experienced marketing manager.

We have professional design department.

We provide excellent after-sales service.

We will do our best for the customer as long as you choosing us.

We promise to solve all the problems during trading process.

We promise our quality and the products will be approved by your side.

We will regularly track level of customer satisfaction.

We have automated the process of providing services.

We focus on quality management.

We apply mechanisms employer flexibility.

FAQ

What should the buyer do before using the masterbatch?

You should confirm the percentage of appending proportion. For example, if using for film blowing with PE material, the required percentage is 4%.

What’s the normal proportion?

The normal proportion is 2% - 4%. But it is not fixed. It depends on the buyer's requirement.

How does the buyer use the masterbatch?

Mix the material and the masterbatch together by the blender mixer according to the appending proportion. If no blender mixer, it can be manual mixed.

Could you give an example for using masterbatch?

For example: Put 100kg PE material and 4kg PE masterbatch into the blender mixer. Continue the film blowing process as normal.

How do the customers customize color?

Customers offer to us the sample of color sheet as the required color. We make our own samples according to customer's sample sent to us.

Is there other way to get the desired color?

We send our sample to customer for test. We produce according to orders after the sample got approved by the customers.

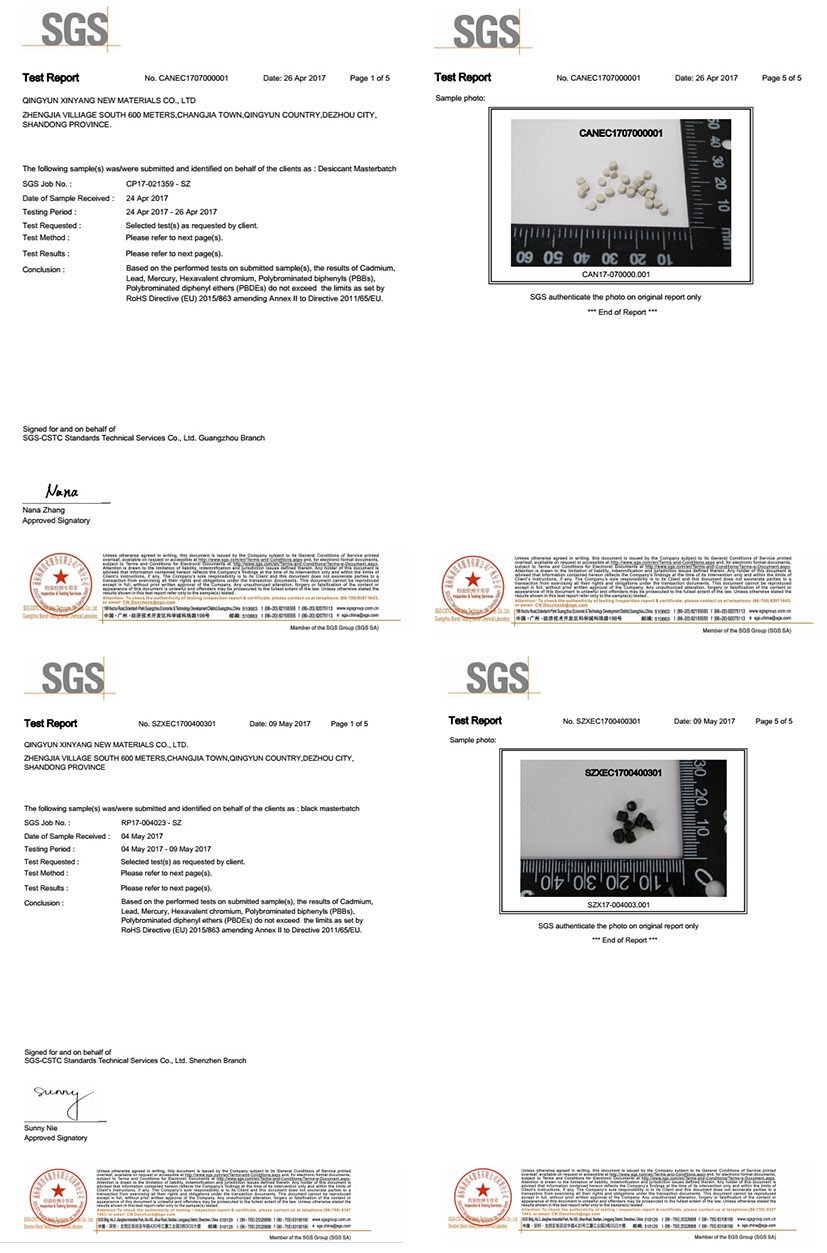

Certification

Contact

Ivy Lee

Email: sales1@xy-masterbatch.com

Tel:+86-0531-88995327

Mobile:+86-18660195311

Whatsapp: +86-18660195311

Address: 600 meters south of Zhengjia Village, Changjia Town, Qingyun County, Dezhou, Shandong, P.R.China