Transparent Filler Masterbatch

- Introduce

Transparent Filler Masterbatch Details

This product is pure white granular material, and can be flexibly prepared to produce all kinds of color products.It contains antioxidants and aging resistant agents, which can prolong the service life of the products.

|

BaSO4 filler masterbatch test data sheet |

|||||

|

Testing item |

Unit/raw material |

Standard value |

Tested value |

Result |

Customized |

|

powder |

NaNO BaSO4 Powder |

100% |

100% |

Qualified |

70%-80% |

|

powder finess |

Nanometer |

100nm |

100nm |

Qualified |

YES |

|

powder content |

% |

82±0.5% |

82.1% |

Qualified |

≤85% |

|

carrier |

PE+ADDITIVE |

18±0.5% |

17.9% |

Qualified |

PE/PP |

|

MFR(190℃ 5kg) |

g/10min |

8-12 |

10.5 |

Qualified |

1-30g/10min |

|

M elting |

℃ |

160 |

160 |

Qualified |

NO |

|

Density |

g/m3 |

2.4-2.7 |

2.5 |

Qualified |

NO |

|

Moisture |

% |

0.1 |

0.1 |

Qualified |

NO |

|

Transference resistance |

Grade |

7-8grade |

7-8grade |

Qualified |

NO |

|

Weather resistance |

Grade |

7-8grade |

7-8grade |

Qualified |

NO |

|

Add ratio |

% |

5%-50% |

5%-50% |

Qualified |

5%-35% |

Transparent Filler Masterbatch advantage

Reducing the cost

Improving machine’s extrusion efficiency

Increases film & mold’s physical properties

Good compatibility

Reducing heat release from burning

Preventing further environmental pollution

Reduce the cost of products

Improve production efficiency

Get good economic benefits

Strengthening the rigidity of the products

Increasing the weight of the products

Rreduce the shrinkage of products

Reduce deformation caused by contraction

Good dispersibility

Good solubility with polypropylene and polyethylene

High Whiteness

Packaging & Shipping

Company information

We always hold the tenet of “ quality first , customer first and service best ” , and stick to innovation and pursue excellence.

We welcome old and new customers all over the world and import & export company & trade merchants in the oversea to talk and cooperate in the future.

Test Equipments

Why choose us?

Our packing bags can be used again and again 10 times to basically be scrapped, and our can be used repeatedly 20 times.

Our masterbatch uses environmental protection technology, save the environmental protection expense.

Our masterbatch is safer to use, and ensure worker safety.

We can provide a complete set of data analysis.

We can provide a large number of mechanical operation images to ensure the quality of production.

We have advanced production technology, constant innovation.

We promise that our product has passed through rigorous test, the quality can be guaranteed and reliable.

We have modern production and testing equipment.

We have high quality raw material, advanced facilities, fine procedures.

We own high productivity and fast delivery.

FAQ

How does the seller make sure what they provide is exactly what the buyer needs?

We will make sample first and confirm with the buyer. After confirm the sample with the buyer, we will produce the formal order.

Could I get a sample for free?

Yes, you can get the sample for free, but should bear the delivery fee.

What should the buyer do before using the masterbatch?

You should confirm the percentage of appending proportion. For example, if using for film blowing with PE material, the required percentage is 4%.

What’s the normal proportion?

The normal proportion is 2% - 4%. But it is not fixed. It depends on the buyer's requirement.

How does the buyer use the masterbatch?

Mix the material and the masterbatch together by the blender mixer according to the appending proportion. If no blender mixer, it can be manual mixed.

Could you give an example for using masterbatch?

For example: Put 100kg PE material and 4kg PE masterbatch into the blender mixer. Continue the film blowing process as normal.

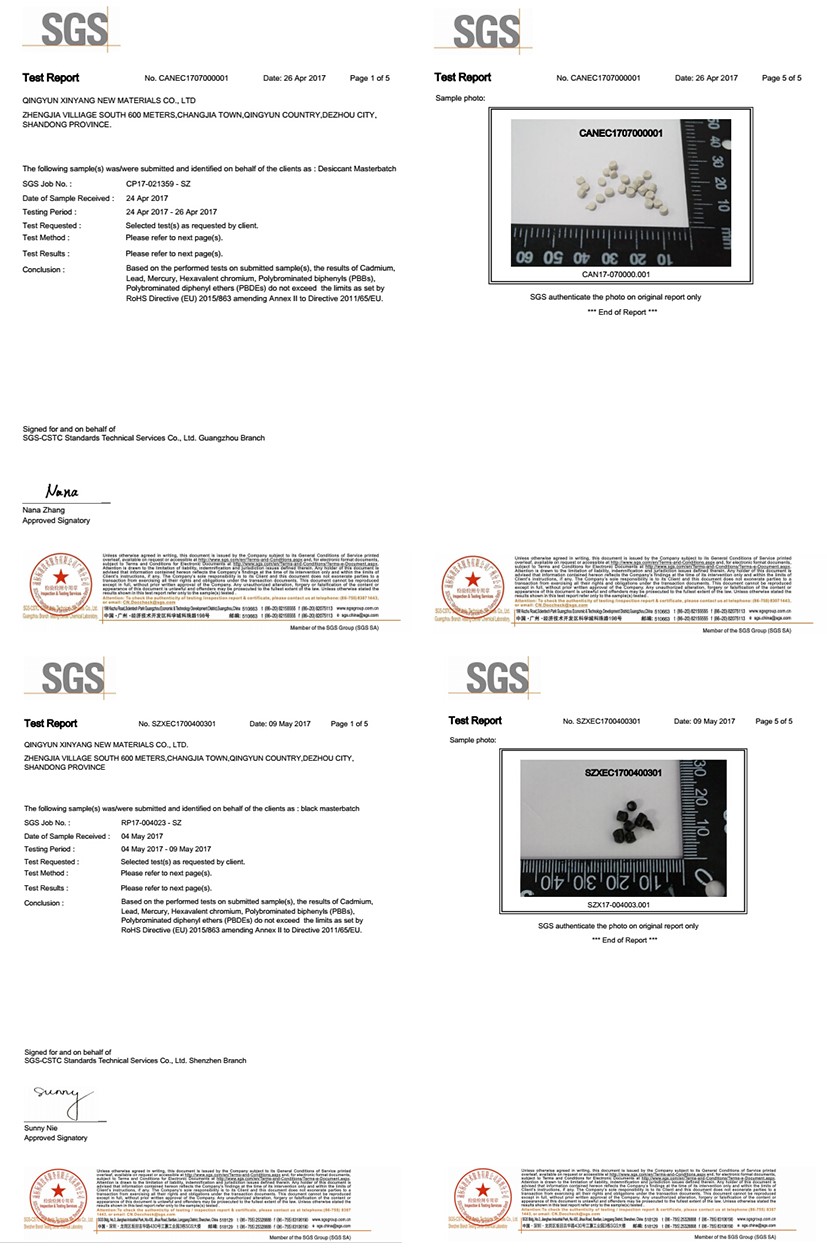

Certification

Contact

Ivy Lee

Email: sales1@xy-masterbatch.com

Tel:+86-0531-88995327

Mobile:+86-18660195311

Whatsapp: +86-18660195311

Address: 600 meters south of Zhengjia Village, Changjia Town, Qingyun County, Dezhou, Shandong, P.R.China