plastic defoamer

- Introduce

Plastic defoamer details

The calcium oxide is reduced to calcium hydroxide, and then the fine particles of calcium hydroxide are evenly dispersed in the plastic products after blended with the resin

|

Desiccant masterbatch |

|

|

Items |

value |

|

Appearance |

granular |

|

Color |

White or grey or black |

|

Calcium Oxide content |

70-80% |

|

Carrier |

PE/PP |

|

Water absorption |

20% |

|

Moisture absorbent weight |

20~25±1,0% |

|

MFI(230°C/10min) |

5~10g/10min |

|

Melting Point (°C) |

120℃ |

|

Density(g/m?) |

1.4+/-0.1g/m? |

|

Volatility |

1.5+/-0.5% |

|

Pellet size of Masterbatch |

2.5micron |

|

Addition Rate(%) |

2-5% |

|

Packing (Net weight) |

25 Kg/ bags Vacuum packaging |

|

Time to keep in Mixture |

20 to 48 hours |

Plastic defoamer advantage

Perfect diffusing

Less effect on products glossing and coloring

Good corrosion resistance

Powerful water absorbing up to its weight 20%

Non-toxic and environment-friendly

Packaging & Shipping

Test Equipments

Why choose us?

We have years of experience on masterbatch producing.

We provide professional talents service for you.

We will offer competitive price with no middleman in trade.

We could provide customized service according to your inquiry.

We have advanced equipments for testing and manufacturing.

We guarantee the product at good quality and competitive price within short lead time.

We provide free sample for 1-5kg to our customers.

We bring forth a wide assortment of masterbatches.

We offer superior quality masterbatches that confirm with the international food contact regulations.

We provide masterbatches with excellent dispersion properties and exceptional whiteness, blackness or colorness index.

We provide colour-matching services for applications that require specific shades.

FAQ

What’s the normal proportion?

The normal proportion is 2% - 4%. But it is not fixed. It depends on the buyer's requirement.

How does the buyer use the masterbatch?

Mix the material and the masterbatch together by the blender mixer according to the appending proportion. If no blender mixer, it can be manual mixed.

Could you give an example for using masterbatch?

For example: Put 100kg PE material and 4kg PE masterbatch into the blender mixer. Continue the film blowing process as normal.

How do the customers customize color?

Customers offer to us the sample of color sheet as the required color. We make our own samples according to customer's sample sent to us.

Is there other way to get the desired color?

We send our sample to customer for test. We produce according to orders after the sample got approved by the customers.

Do we provide free sample of the products?

Of course, please feel free to tell me your specific requirements, and then we will make the corresponding customized sample to you.

What’s your shipping port?

Shenzhen, Guangzhou, Shanghai, Tianjin, Qingdao etc.

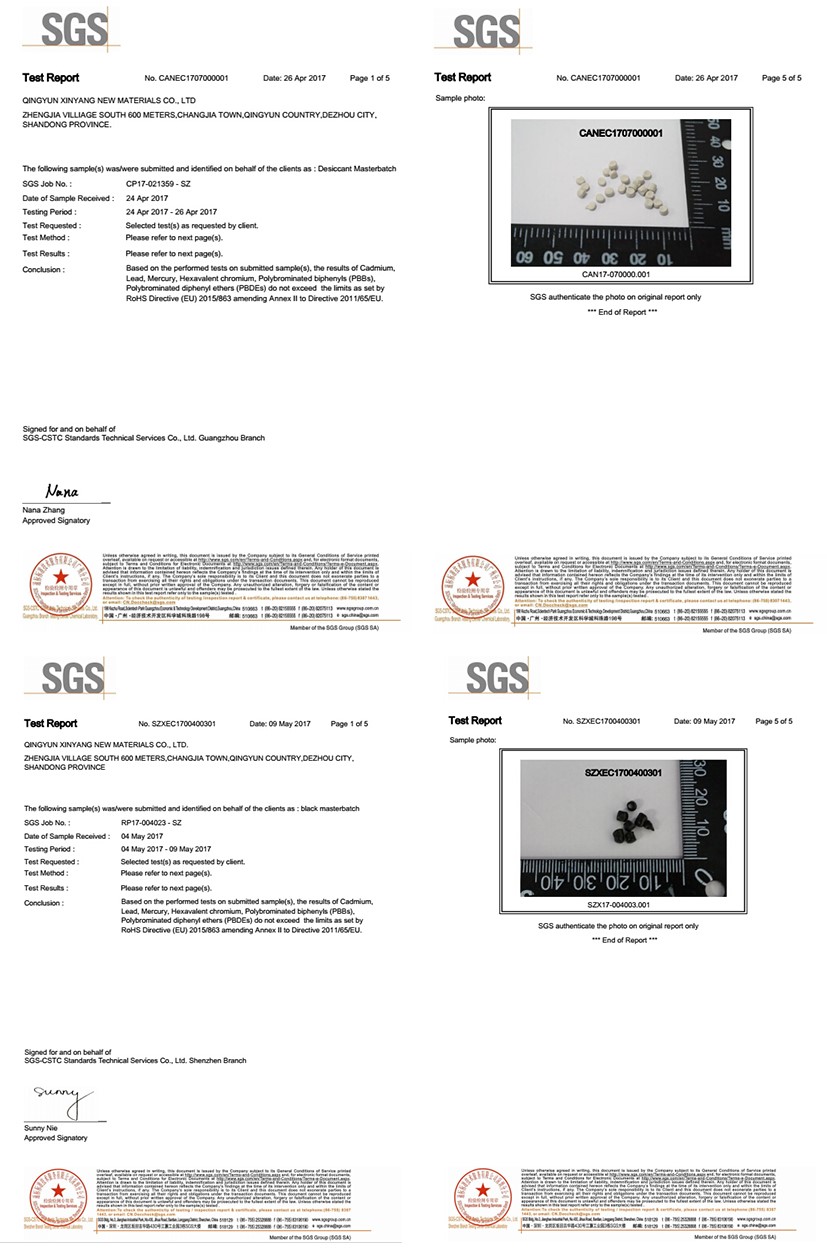

Certification

Company information

We own advanced equipments, skilled workers, experienced technician and strong technological innovative ability.

Contact

Ivy Lee

Email: sales1@xy-masterbatch.com

Tel:+86-0531-88995327

Mobile:+86-18660195311

Whatsapp: +86-18660195311

Address: 600 meters south of Zhengjia Village, Changjia Town, Qingyun County, Dezhou, Shandong, P.R.China