Color Plastic Filler Masterbatch

- Introduce

Color Plastic Filler Masterbatch details

CaCO3 filler masterbatch uses PE/PP, styrene resin as carrier, takes calcium carbonate as the main element, compound with paraffin wax and other additives, extruded by high speed mixer and then cut by air cooling.

|

Color masterbatch test data sheet |

|

|

Density |

0.6-1.0 |

|

Heat Resistance |

300℃ |

|

Compatibility |

LLDPE/HDPE/PE/PP/ABS/PS/PA/PVC/EVA |

|

Melting Point |

120℃ |

|

MFI |

30g/10min |

|

MFI(21.6kg/190℃) |

50g110 min |

|

Moisture |

<0.3 |

|

Moisture content |

≤0.15% |

|

Recommend addition proportion |

Customers can change the addition proportion according to the needs, the ratio that we recommend is 1-4 % |

|

Resin |

PE |

|

Tinting strength |

95~105% |

|

Transference resistance |

5 grade |

|

Volatility |

<0.1 % |

|

Pigment Content |

20-45% |

|

Gloss grades |

High gloss |

Color Plastic Filler Masterbatch advantage

No net plugging

Nontoxic

No odor

No corrosiveness

Harmless to the human body

Wide range of colors

High brightness

Uniform dispersion

Strong tinting strength

Non-toxic and environment-friendly

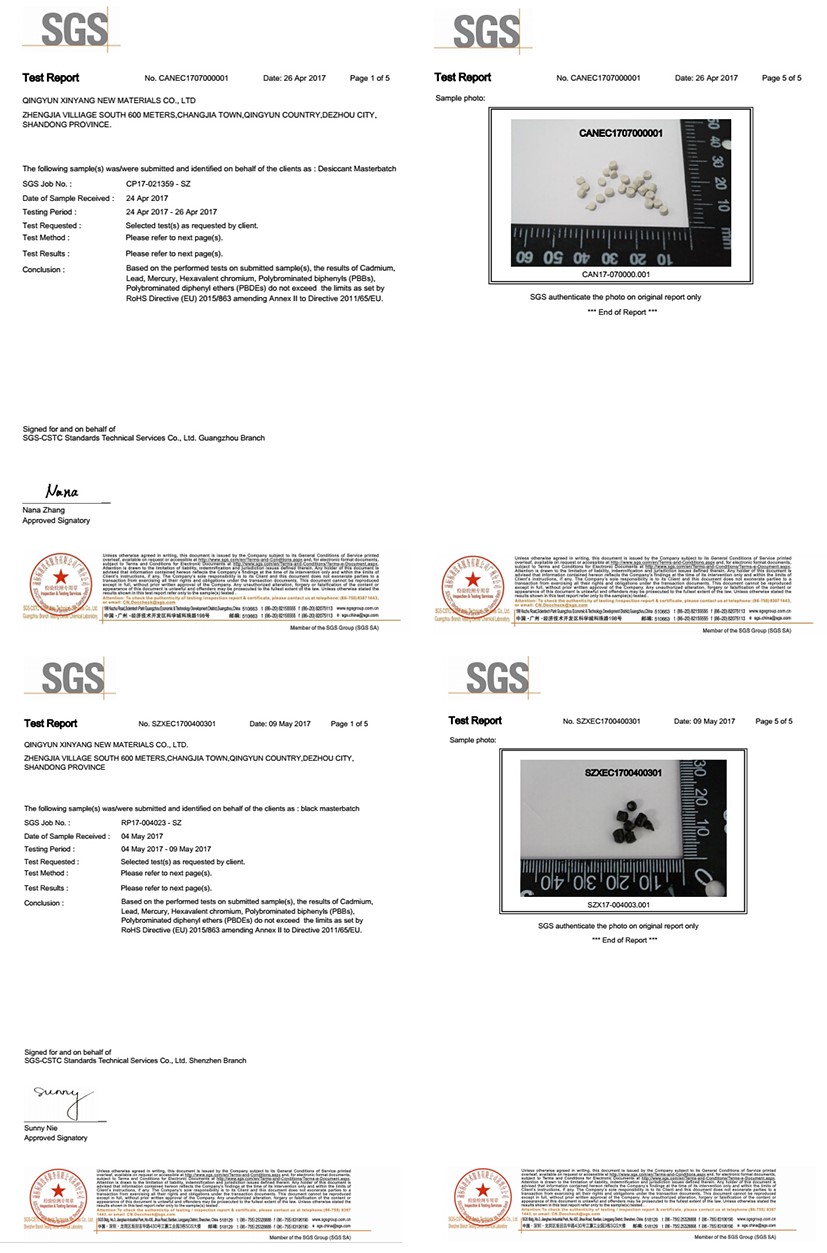

Certified by RoHS & SGS& ISO9001

Good dispersing & heat resistance

High concentration pigment with bright colors

High blackness

High brightness

Uniform dispersion

High tinting strength

Excellent dispersion

Packaging & Shipping

Why choose us?

We can provide a large number of mechanical operation images to ensure the quality of production.

We have advanced production technology, constant innovation.

We promise that our product has passed through rigorous test, the quality can be guaranteed and reliable.

We have modern production and testing equipment.

We have high quality raw material, advanced facilities, fine procedures.

We own high productivity and fast delivery.

We have leading level R & D department.

We have strong production capacity, high speed delivery.

We provide good quality product with competitive price.

We have experienced marketing manager.

We have professional design department.

We provide excellent after-sales service.

We will do our best for the customer as long as you choosing us.

We promise to solve all the problems during trading process.

We promise our quality and the products will be approved by your side.

FAQ

What should the buyer do before using the masterbatch?

You should confirm the percentage of appending proportion. For example, if using for film blowing with PE material, the required percentage is 4%.

What’s the normal proportion?

The normal proportion is 2% - 4%. But it is not fixed. It depends on the buyer's requirement.

How does the buyer use the masterbatch?

Mix the material and the masterbatch together by the blender mixer according to the appending proportion. If no blender mixer, it can be manual mixed.

Could you give an example for using masterbatch?

For example: Put 100kg PE material and 4kg PE masterbatch into the blender mixer. Continue the film blowing process as normal.

How do the customers customize color?

Customers offer to us the sample of color sheet as the required color. We make our own samples according to customer's sample sent to us.

Certification

Company information

Our company is qualified as a supplier of numerous domestic and international companies, and we have won a high praise from foreign and domestic customers.

Test Equipments

Contact

Email: sales1@xy-masterbatch.com

Tel:+86-0531-88995327

Mobile:+86-18660195311

Whatsapp: +86-18660195311

Address: 600 meters south of Zhengjia Village, Changjia Town, Qingyun County, Dezhou, Shandong, P.R.China

Copyright © 2017 Qingyun Xinyang New Materials Co., Ltd.