CaO desiccant masterbatch

- Introduce

CaO desiccant masterbatch description

CaO desiccant masterbatch is plastic defoamer masterbatch, also known as plastic desiccant, dehumidification masterbatch, absorbent masterbatch, is widely used in injection molding, drawing, blown film, extubation and other plastic products in the production process.CaO desiccant masterbatch specifications

|

defoaming masterbatch test data sheet |

|||||

|

Testing item |

Unit/raw material |

Standard value |

Tested value |

Result |

Customized |

|

CaO content |

CaO |

80% |

80% |

Qualified |

70%-80% |

|

Carrier |

PE(virgin)+additives |

20% |

20% |

Qualified |

PE、PP、ABS、PS |

|

Filler |

CaO |

0% |

0% |

Qualified |

50%-80% |

|

MFR(190℃ 21.6kg) |

g/10min |

35-50 |

35-50 |

Qualified |

35-50 |

|

Melting |

℃ |

105℃ |

105℃ |

Qualified |

105-180℃ |

|

Density |

g/m3 |

1.75 |

1.75 |

Qualified |

1.75±0.1 |

|

Moisture |

% |

0.1% |

0.1% |

Qualified |

NO |

|

Heat resistance |

℃ |

300℃ |

300℃ |

Qualified |

NO |

|

Transference resistance |

Grade |

7-8grade |

7-8grade |

Qualified |

NO |

|

Weather resistance |

Grade |

7-8grade |

7-8grade |

Qualified |

NO |

|

Add ratio |

% |

2%-5% |

2%-5% |

Qualified |

2%-5% |

CaO desiccant masterbatch advantage Better water absorption

Perfect diffusing

Less effect on products glossing and coloring

Good corrosion resistance

Powerful water absorbing up to its weight 20%

Non-toxic and environment-friendly

No hurt on worker

Packaging & Shipping

Why choose us?

A broad standard color range available from the stock as well as tailor made products develop according to customer requirement.We like to develop a long term business relationship with you.

Our packing bags can be used again and again 10 times to basically be scrapped, and our can be used repeatedly 20 times.

Our masterbatch uses environmental protection technology, save the environmental protection expense.

Our masterbatch is safer to use, and ensure worker safety.

We can provide a complete set of data analysis.

We can provide a large number of mechanical operation images to ensure the quality of production.

We will do our best for the customer as long as you choosing us.

We promise to solve all the problems during trading process.

We promise our quality and the products will be approved by your side.

We will regularly track level of customer satisfaction.

We have automated the process of providing services.

We focus on quality management.

We apply mechanisms employer flexibility.

FAQ

What should the buyer do before using the masterbatch?You should confirm the percentage of appending proportion. For example, if using for film blowing with PE material, the required percentage is 4%.

What’s the normal proportion?

The normal proportion is 2% - 4%. But it is not fixed. It depends on the buyer's requirement.

How does the buyer use the masterbatch?

Mix the material and the masterbatch together by the blender mixer according to the appending proportion. If no blender mixer, it can be manual mixed.

Do we provide free sample of the products?

Of course, please feel free to tell me your specific requirements, and then we will make the corresponding customized sample to you.

What’s your shipping port?

Shenzhen, Guangzhou, Shanghai, Tianjin, Qingdao etc.

What is the shipping terms?

FOB Shenzhen, Guangzhou, Shanghai, Tianjin, Qingdao etc.

How about your payment?

T/T, L/C, western union.

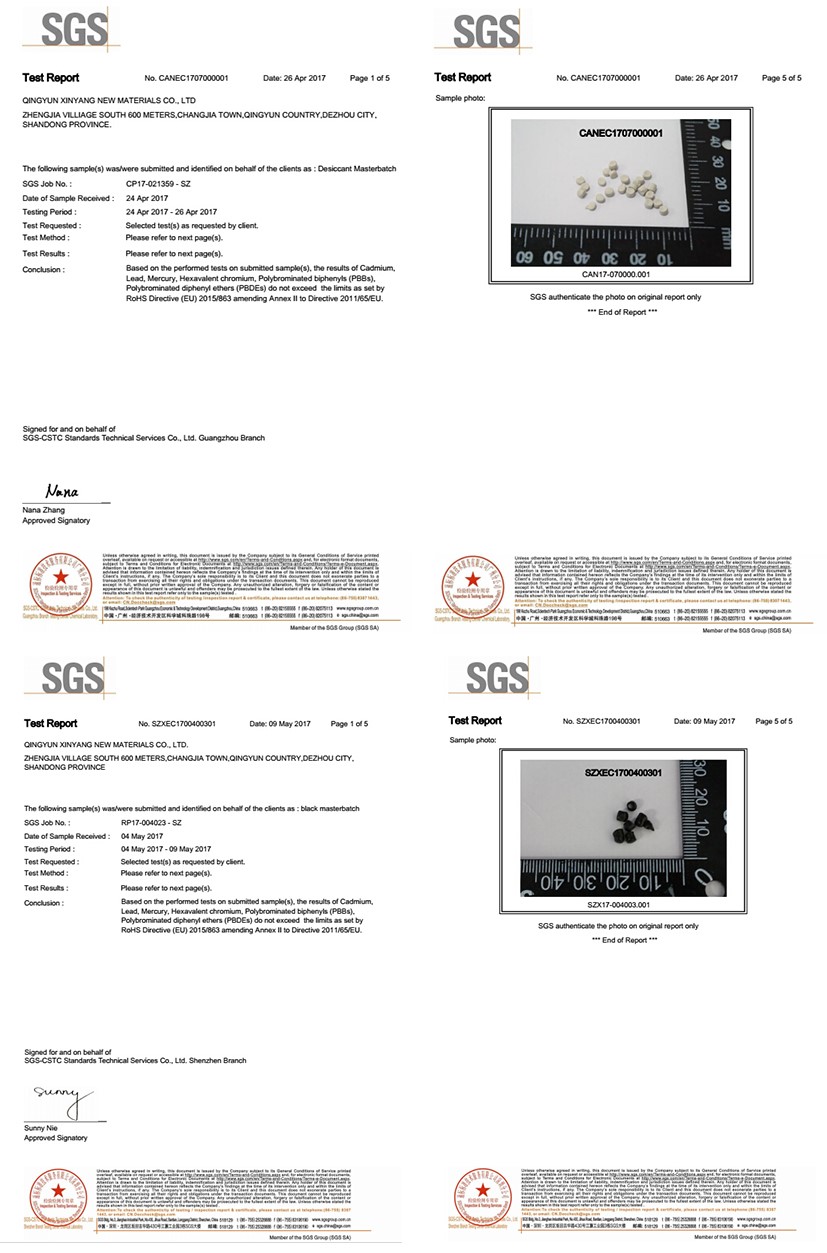

Certification

Company profile

Including the management team, research team, production staff, we have total 100 employees. Our workshop and office area is 1000m2. In addition, five masterbatch production lines were built to produce PE, PP, PVC, PS, PC, EVA and ABS masterbatch, the annual capacity is 60000 tons. Our products are all manufactured according to the RoHS standard, and FDA certification is also available to the products of our company.

Contact

Ivy LeeEmail: sales1@xy-masterbatch.com

Tel:+86-0531-88995327

Mobile:+86-18660195311

Whatsapp: +86-18660195311

Address: 600 meters south of Zhengjia Village, Changjia Town, Qingyun County, Dezhou, Shandong, P.R.China