color masterbatches

- Introduce

Color masterbatches description

It’s widely used in packaging film, bottle, cap, hose, all kinds of containers, toys, household appliances, office suppliers, automotive trim and all kinds of building pipe material. They are suitable for extrusion, blow molding, casting, injection molding.

Color masterbatches specifications

|

COLOR MASTERBATCH DATA SHEET |

|||||

|

TESTING ITEM |

UNIT/RAW MATERIAL |

STANDARD VALUE |

TESTED VALUE |

RESULT |

CUSTOMIZED |

|

PIGMENT GRADE |

% |

5-70% |

16.0% |

QUALIFIED |

AVAILABLE |

|

PIGMENT GRADE |

Organic/Inorganic |

as requested |

as tested |

QUALIFIED |

AVAILABLE |

|

CARRIER |

PE, PP, PET, ABS, PS, PA, PC |

10-95% |

30.0% |

QUALIFIED |

AVAILABLE |

|

ADD RATIO |

% |

0.5%-45% |

as tested |

QUALIFIED |

AVAILABLE |

|

MFI(190℃ 21.6KG) |

g/10min |

1-45g/10min |

16 |

QUALIFIED |

AVAILABLE |

|

MELTING |

℃ |

140℃ |

105 |

QUALIFIED |

NO |

|

DENSITY |

g/m3 |

0.95-1.7 |

1.25 |

QUALIFIED |

AVAILABLE |

|

MOISTURE |

% |

0.1% |

|

QUALIFIED |

AVAILABLE |

|

HEAT RESISTANCE |

℃ |

as requested |

180 |

QUALIFIED |

AVAILABLE |

|

TRANSFERENCE RESISTANCE |

4-8GRADE |

as requested |

6 |

QUALIFIED |

AVAILABLE |

|

WEATHER RESISTANCE |

5-8GRADE |

as requested |

5 |

QUALIFIED |

AVAILABLE |

Color masterbatches advantage

High brightness

Uniform dispersionHigh tinting strength

Excellent dispersion

Good heat-resistance

With wide application

High concentration pigment

Good dyeing property

Strong shading

Strong tinting power

Uniform dispersion

Good solubility

Environment-friendly

Test Equipments

Packaging & Shipping

Why choose us?

Our masterbatch uses environmental protection technology, save the environmental protection expense.

Our masterbatch is safer to use, and ensure worker safety.

We can provide a complete set of data analysis.

We can provide a large number of mechanical operation images to ensure the quality of production.

We have advanced production technology, constant innovation.

We promise that our product has passed through rigorous test, the quality can be guaranteed and reliable

We have modern production and testing equipment.

We have high quality raw material, advanced facilities, fine procedures.

We focus on quality management.

We apply mechanisms employer flexibility.

We apply differentiated pricing policy over time.

We have accurate demand forecast.

We are manufacturer and we have our own factory.

We can offer you a competitive price and high quality than other suppliers.

We make sure all the products will be inspected strictly before loading. To make sure that our clients can get the satisfied and correct goods from us!

We promise that pay back all loss for our customer if any mistake made by our side.

We will make the shipment within 7 days after confirming the payment.

FAQ

How does the seller make sure what they provide is exactly what the buyer needs?

We will make sample first and confirm with the buyer. After confirm the sample with the buyer, we will produce the formal order.Could I get a sample for free?

Yes, you can get the sample for free, but should bear the delivery fee.

What should the buyer do before using the masterbatch?

You should confirm the percentage of appending proportion. For example, if using for film blowing with PE material, the required percentage is 4%.

What’s the normal proportion?

The normal proportion is 2% - 4%. But it is not fixed. It depends on the buyer's requirement.

How to meet my final products’ need to be protected from static and raging fire?

If your final products need to be protected from static and raging fire, we can add anti-static and flame retardant additive agent in the masterbatch to make its surface more cleaner, avoid dust in the air, and improve the electronic products safety level, avoid raging fire.

Why do you use masterbatch with virgin plastic carrier?

Since masterbatch is high pigment concentration material, so we need high quality virgin polymer carrier to make this compound, to ensure the excellent property and performance.

What’s the advantage of virgin polymer carrier masterbatch?

Virgin polymer carrier masterbatch will disperse better, especially in resisting high working temperature, while recycled plastic carrier is easier to cause color burn.

Company profile

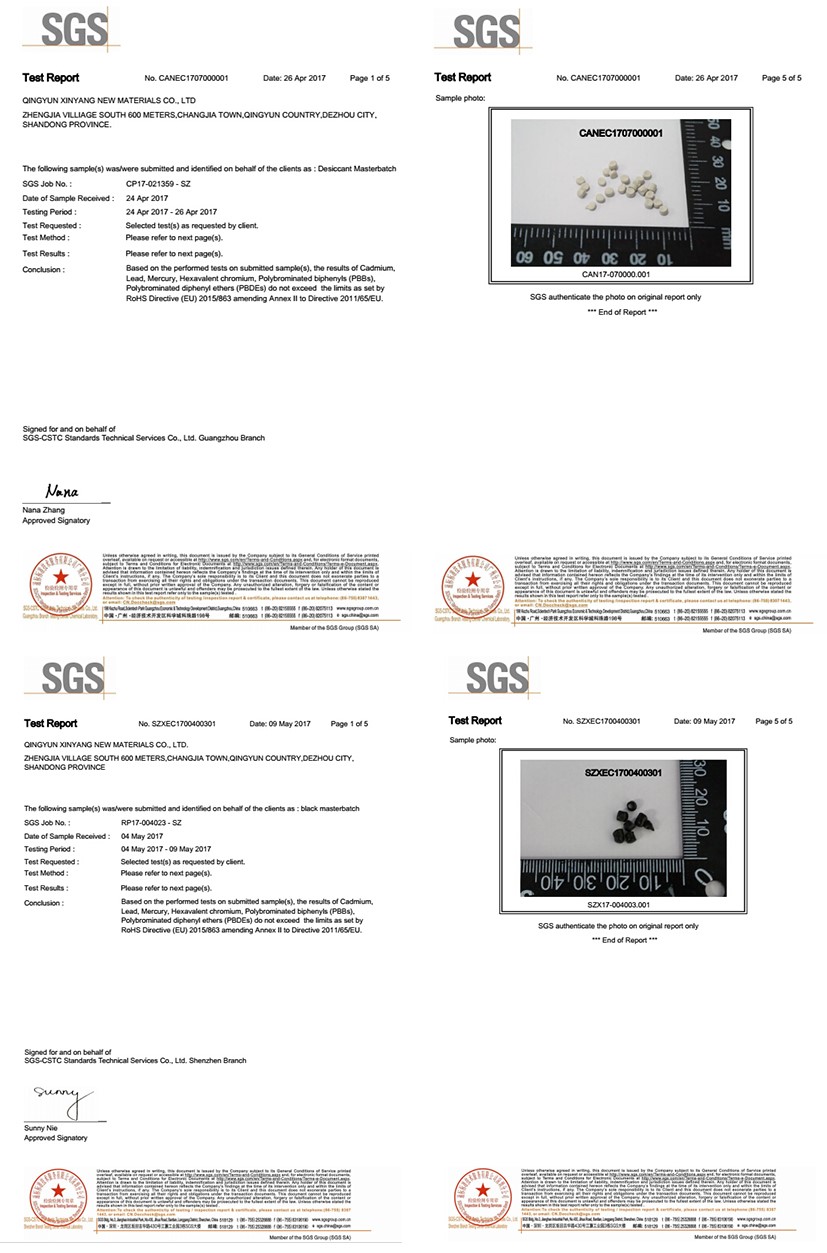

Certification

Contact

Ivy Lee

Email: sales1@xy-masterbatch.com

Tel:+86-0531-88995327

Mobile:+86-18660195311

Whatsapp: +86-18660195311

Address: 600 meters south of Zhengjia Village, Changjia Town, Qingyun County, Dezhou, Shandong, P.R.China