You are here:Home> Products

Na2SO4 content: 70%

Adding ratio:5%-40%

Place of Origin:Shandong, China (Mainland)

Color:White, gray white

Appearance:round or flat round particles

Masterbatch Carrier:PE,PP

Application:Film blowing, injection, blowing molding, drawing, Extrusion

Dispersion:colorless, streaks

Migration resistance:≥4 level

Light resistance:4-8 grade

Certification:Available

Packing:25kg/bag

Sodium sulfate filler masterbatch details

Barium sulfate filler masterbatch uses PE/PP , styrene resin as carrier, takes barium sulfate as the main element, compound with paraffin wax and other additives, extruded by high speed mixer and then cut by air cooling. Barium sulfate mesh depends on customer’s use effect.

|

NaSO4 filler masterbatch test data sheet |

|||||

|

Testing item |

Unit/raw material |

Standard value |

Tested value |

Result |

Customized |

|

powder |

waterless NaSO4 |

100% |

100% |

Qualified |

70%-80% |

|

powder finess |

mesh |

2000 |

2000 |

Qualified |

PE、PP、ABS、PS |

|

powder content |

% |

81.6±0.5% |

83.7% |

Qualified |

≤85% |

|

carrier |

PE+ADDITIVE |

18.4±0.5% |

16.3±0.5% |

Qualified |

PE/PP |

|

MFR(190℃ 5kg) |

g/10min |

8-12 |

10.5 |

Qualified |

1-30g/10min |

|

Melting |

℃ |

160 |

160 |

Qualified |

NO |

|

Density |

g/m3 |

1.7-1.9 |

1.7-1.9 |

Qualified |

NO |

|

Moisture |

% |

0.1 |

0.1 |

Qualified |

NO |

|

Transference resistance |

Grade |

7-8grade |

7-8grade |

Qualified |

NO |

|

Weather resistance |

Grade |

7-8grade |

7-8grade |

Qualified |

NO |

|

Add ratio |

% |

5%-35% |

5%-35% |

Qualified |

5%-35% |

Sodium sulfate filler masterbatch advantage

Get good economic benefits

Packaging & Shipping

We have high quality raw material, advanced facilities, fine procedures.

Company information

With the professional technical team, the continuous improvement of the core competitiveness of the enterprise, Our company has set up a good social image in the development.

Test Equipments

FAQ

What should the buyer do before using the masterbatch?

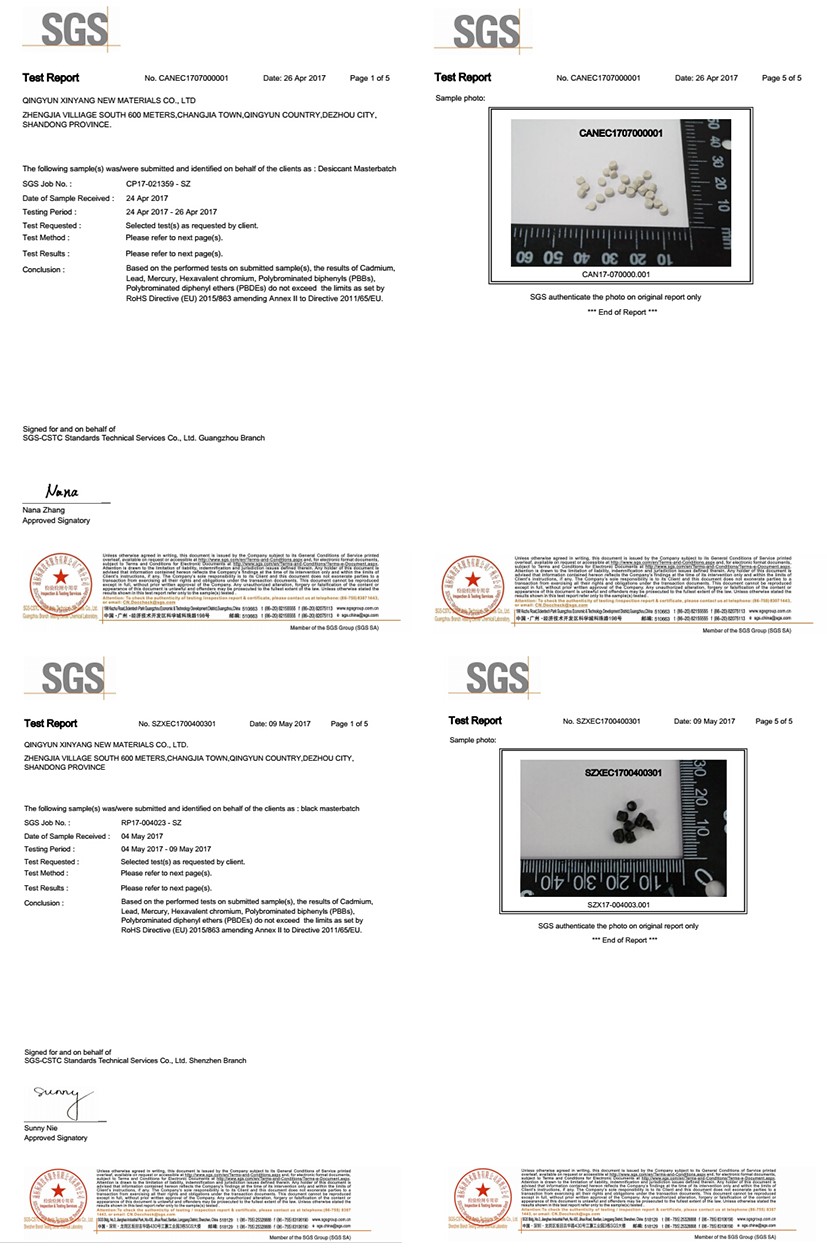

Certification

Contact

Ivy Lee

Copyright © 2017 Qingyun Xinyang New Materials Co., Ltd. All rights reserved. 备案号:鲁ICP备15028652号-2

鲁公网安备 37142302000114号

鲁公网安备 37142302000114号