CaCO3 filler masterbatches for PP application description

CaCO3 filler masterbatch uses PE/PP, styrene resin as carrier, takes calcium carbonate as the main element, compound with paraffin wax and other additives, extruded by high speed mixer and then cut by air cooling. Calcium carbonate’s mesh number depends on customer’s use effect.

|

CaCO3 filler masterbatch

|

|

Item

|

value

|

|

CaCO3 content

|

70-80%

|

|

CaCO3 particle

size

|

Malvern

Mastersizer 2000

|

|

MFI

|

2-30g/10min

|

|

density

|

1.8-2.2g/m3

|

|

Pellet size of

masterbatch

|

3.5*3.5 mm

|

|

Addition rate

|

15-30%

|

|

color

|

white black

|

|

Appearance

|

granules

|

CaCO3 filler masterbatches for PP application addvantage

Increase the tensile strength

Reducing the cost

Improving machine’s extrusion efficiency

Increases film & mold’s physical properties

Good compatibility

Reducing heat release from burning

Preventing further environmental pollution

Reduce the cost of products

Improve production efficiency

Get good economic benefits

Strengthening the rigidity of the products

Increasing the weight of the products

Rreduce the shrinkage of products

Reduce deformation caused by contraction

Good dispersibility

Good solubility with polypropylene and polyethylene

Packaging & Shipping

Why choose us?

We like to develop a long term business relationship with you.

Our packing bags can be used again and again 10 times to basically be scrapped, and our can be used repeatedly 20 times.

Our masterbatch uses environmental protection technology, save the environmental protection expense.

Our masterbatch is safer to use, and ensure worker safety.

We can provide a complete set of data analysis.

We can provide a large number of mechanical operation images to ensure the quality of production.

We own high productivity and fast delivery.

We have leading level R & D department.

We have strong production capacity, high speed delivery.

We provide good quality product with competitive price.

We have experienced marketing manager.

We have professional design department.

We provide excellent after-sales service.

FAQ

How does the seller make sure what they provide is exactly what the buyer needs?

We will make sample first and confirm with the buyer. After confirm the sample with the buyer, we will produce the formal order.

Could I get a sample for free?

Yes, you can get the sample for free, but should bear the delivery fee.

What should the buyer do before using the masterbatch?

You should confirm the percentage of appending proportion. For example, if using for film blowing with PE material, the required percentage is 4%.

Is there other way to get the desired color?

We send our sample to customer for test. We produce according to orders after the sample got approved by the customers.

Do we provide free sample of the products?

Of course, please feel free to tell me your specific requirements, and then we will make the corresponding customized sample to you.

What’s your shipping port?

Shenzhen, Guangzhou, Shanghai, Tianjin, Qingdao etc.

What is the shipping terms?

FOB Shenzhen, Guangzhou, Shanghai, Tianjin, Qingdao etc.

How about your payment?

T/T, L/C, western union.

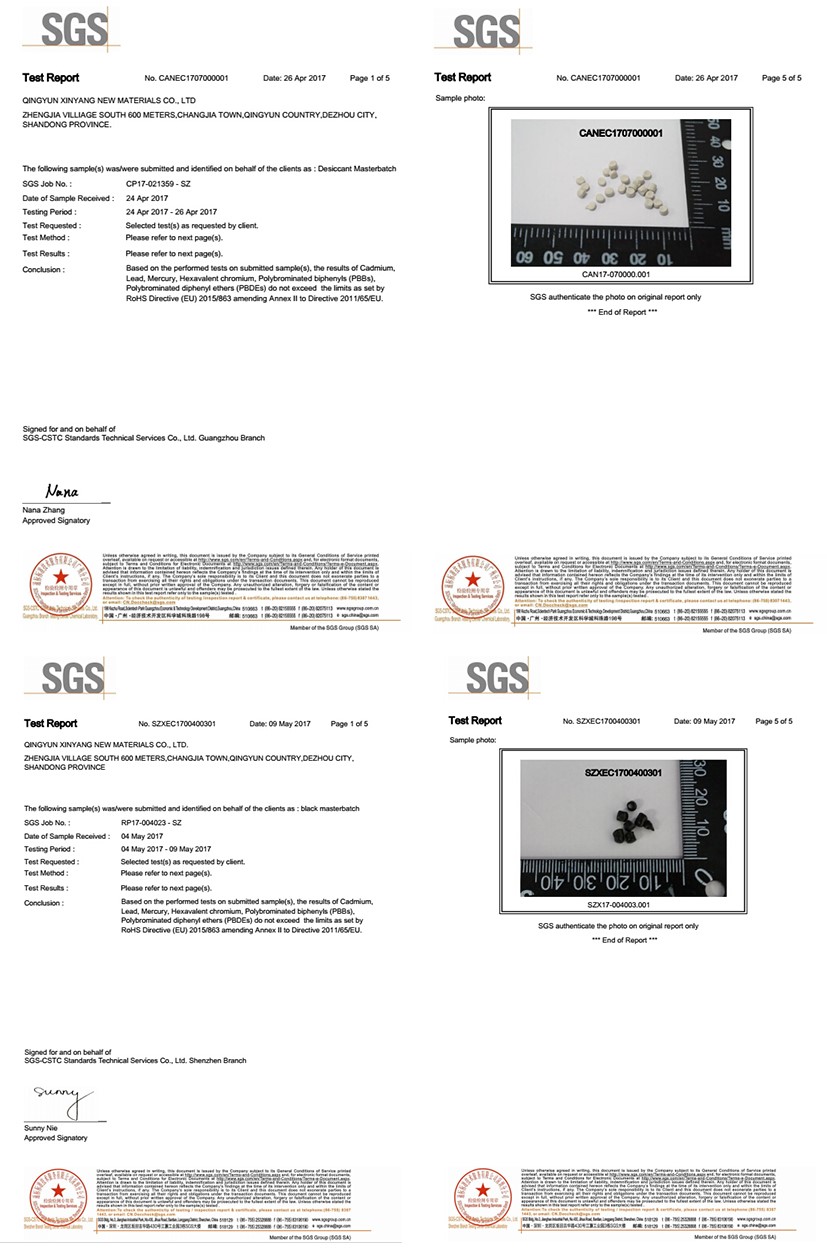

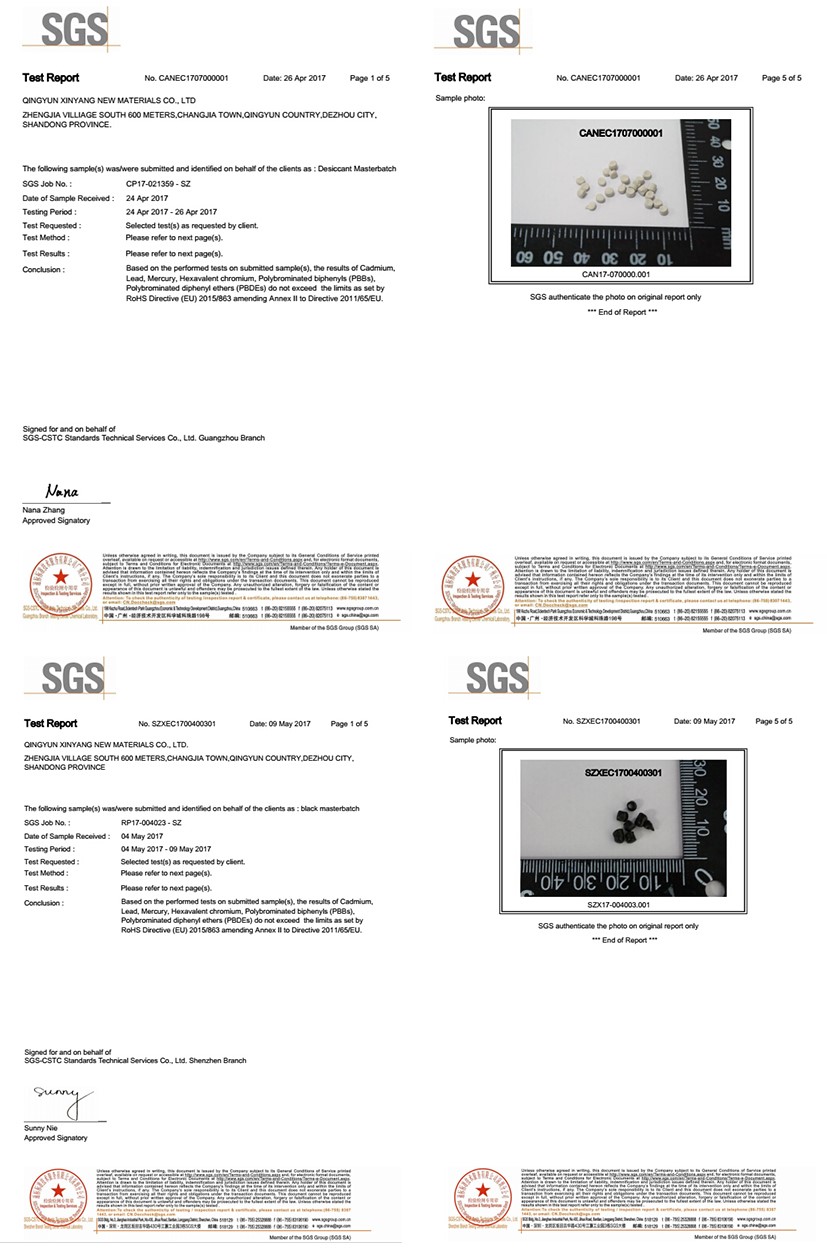

Certification

Company profile

Xinyang New Materials Co., Ltd is a new technology enterprise

specializing in the development and production of plastic masterbatch.

Contact

Ivy Lee

Email: sales1@xy-masterbatch.com

Tel:+86-0531-88995327

Mobile:+86-18660195311

Whatsapp: +86-18660195311

Address: 600 meters south of Zhengjia Village, Changjia Town, Qingyun County, Dezhou, Shandong, P.R.China

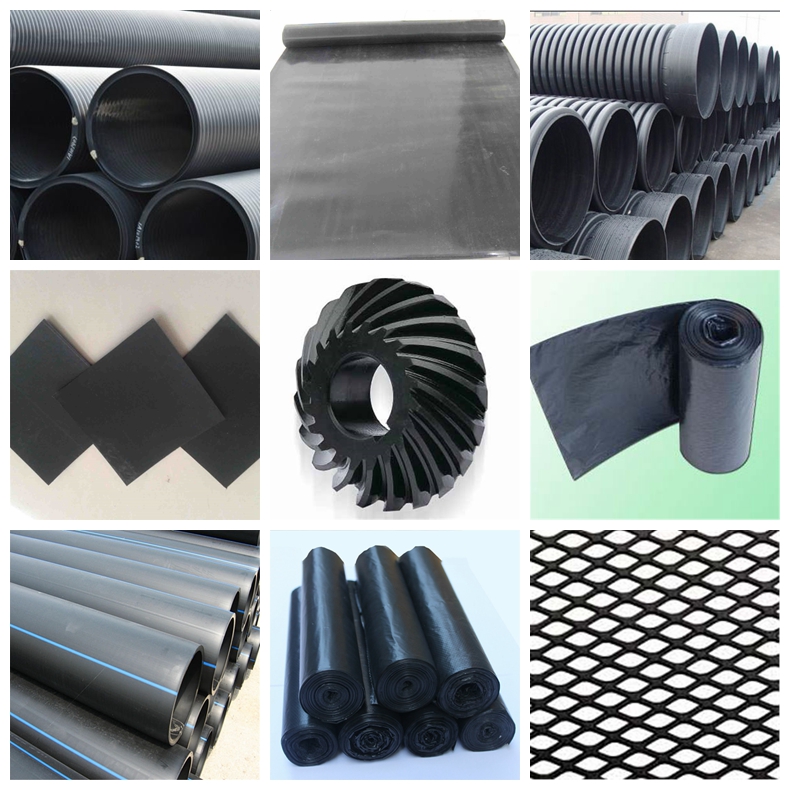

CaCO3 filler masterbatches for PP application applications

Injection Molding (Box, Containers, Chairs, Crates, Buckets, Battery, cases, Hangers, etc.)

Injection Molding (Automotive, Electronic, Construction, House wares, Furniture, Toys, etc.)

Extrusion Molding (Sheet, Pipe, Wire & Cable, etc.)

Film (shopping bags, casting film, multilayer film, etc.)

Fiber (Carpet, Textiles, Upholstery, etc.)

Blow Molding (Medical & Cosmetic Container, Lubricant & Paint Container, etc)

鲁公网安备 37142302000114号

鲁公网安备 37142302000114号